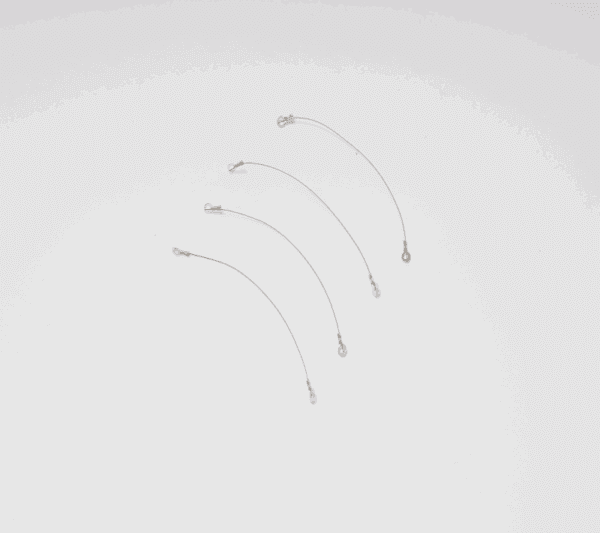

Nitinol Alloy Wire for Endoscopic and Industrial Applications

Our nitinol alloy wire is designed for outstanding performance across both medical and industrial fields. Made from advanced nickel-titanium material, it offers shape memory, excellent flexibility, and high biocompatibility. As a result, it performs reliably under stress while resisting corrosion and fatigue.

Medical-Grade Nickel Titanium Built for Performance

We use medical-grade nitinol, a carefully balanced nickel-titanium alloy known for superelasticity and shape recovery. Thanks to its biocompatible nature, it’s ideal for surgical tools that require long-term contact with human tissue.

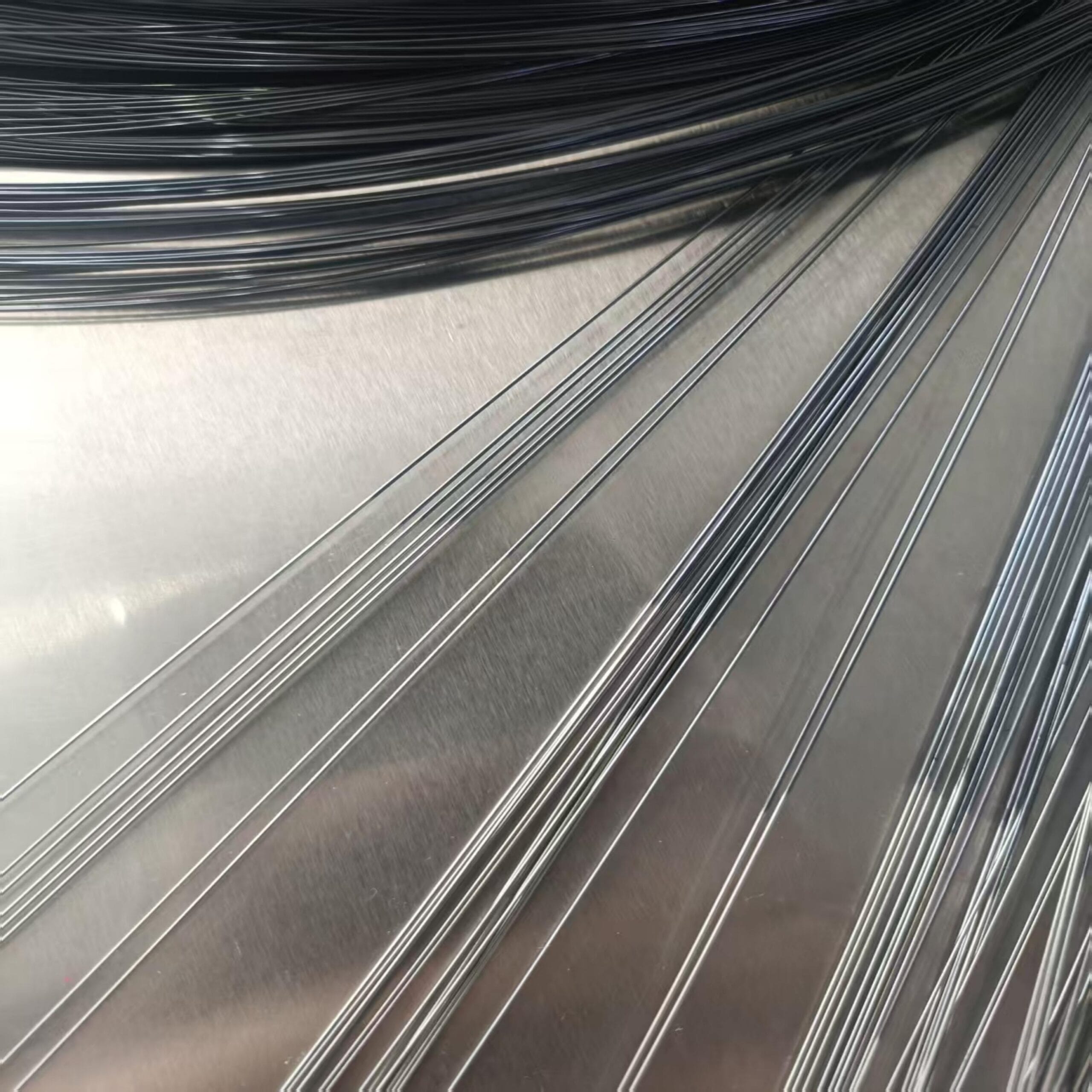

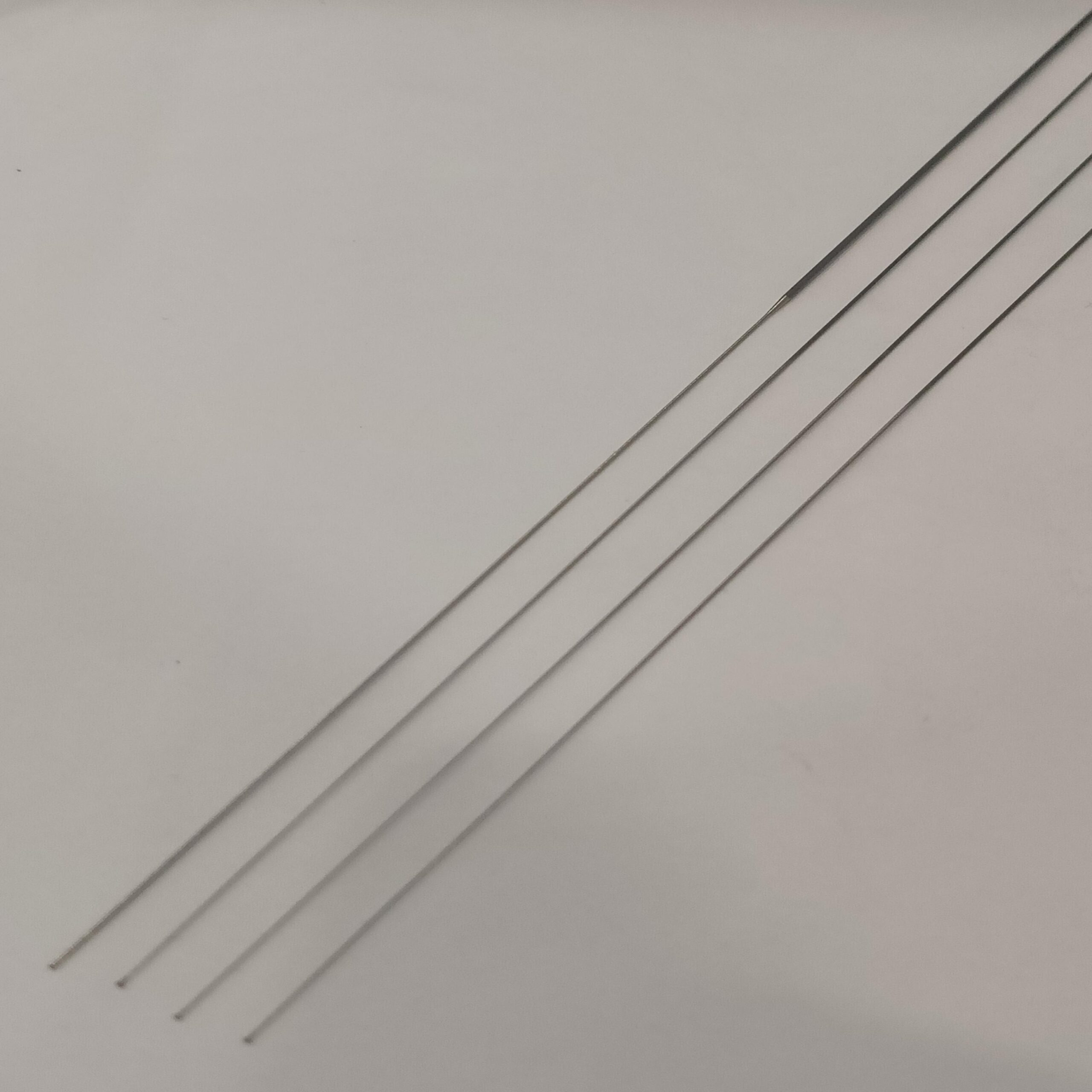

Surface Finishes Tailored to Your Needs

To meet a variety of application requirements, we offer multiple surface treatment options. For example, electro-polishing produces a smooth, low-friction finish perfect for surgical instruments. Meanwhile, mechanical polishing ensures a uniform texture for industrial tools. Each wire receives finishing that eliminates burrs and micro-cracks, which helps reduce contamination and improve precision.

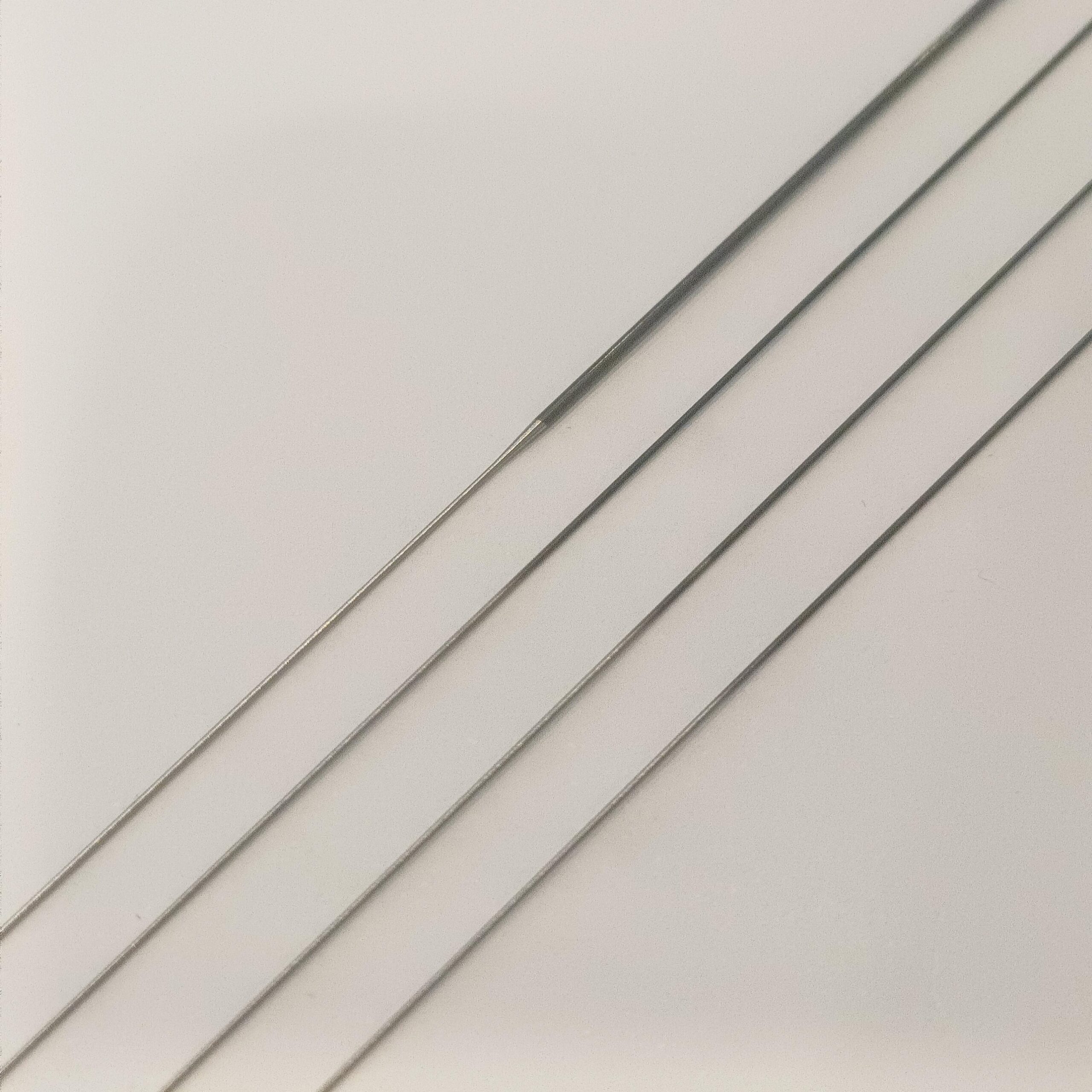

Custom Diameter Range with Precision Tolerances

You can choose wire diameters ranging from 0.05 mm to 3.0 mm. Ultra-thin options (0.05–0.5 mm) are perfect for minimally invasive procedures, whereas thicker wires (1.0–3.0 mm) provide the strength needed for grinding and heavy-duty tasks. Additionally, tight tolerances (±0.001 mm) ensure every wire meets exact specifications.

Broad Application Versatility

Whether in surgical devices or high-precision industrial tools, this wire performs consistently. In healthcare, it’s commonly used in endoscopic scissors, biopsy tools, and orthodontic appliances. Engineers also rely on it for micro-springs, robotic arms, and vascular guidewires. Furthermore, industries such as aerospace and electronics use it for grinding, connector pins, and watch springs.

Why Work With Us?

We’ve specialized in nitinol alloy wire production for over 15 years. Unlike generic suppliers, we use vacuum arc remelting to ensure consistent alloy composition and remove impurities. Moreover, every batch undergoes rigorous tensile, thermal, and surface testing.

Because we know time matters, we offer rapid prototyping services with custom samples delivered in just 72 hours. You can also benefit from our flexible order quantities—ideal for both small R&D runs and high-volume production. Our competitive pricing and 24/7 support help you meet project goals without sacrificing quality.

Many medical professionals choose our wire for its reliable cutting performance and clean finishes. At the same time, industrial users value its durability in high-speed equipment. With fast global shipping and expert guidance, we make it easy to get the right solution for your needs.

Reviews

There are no reviews yet.