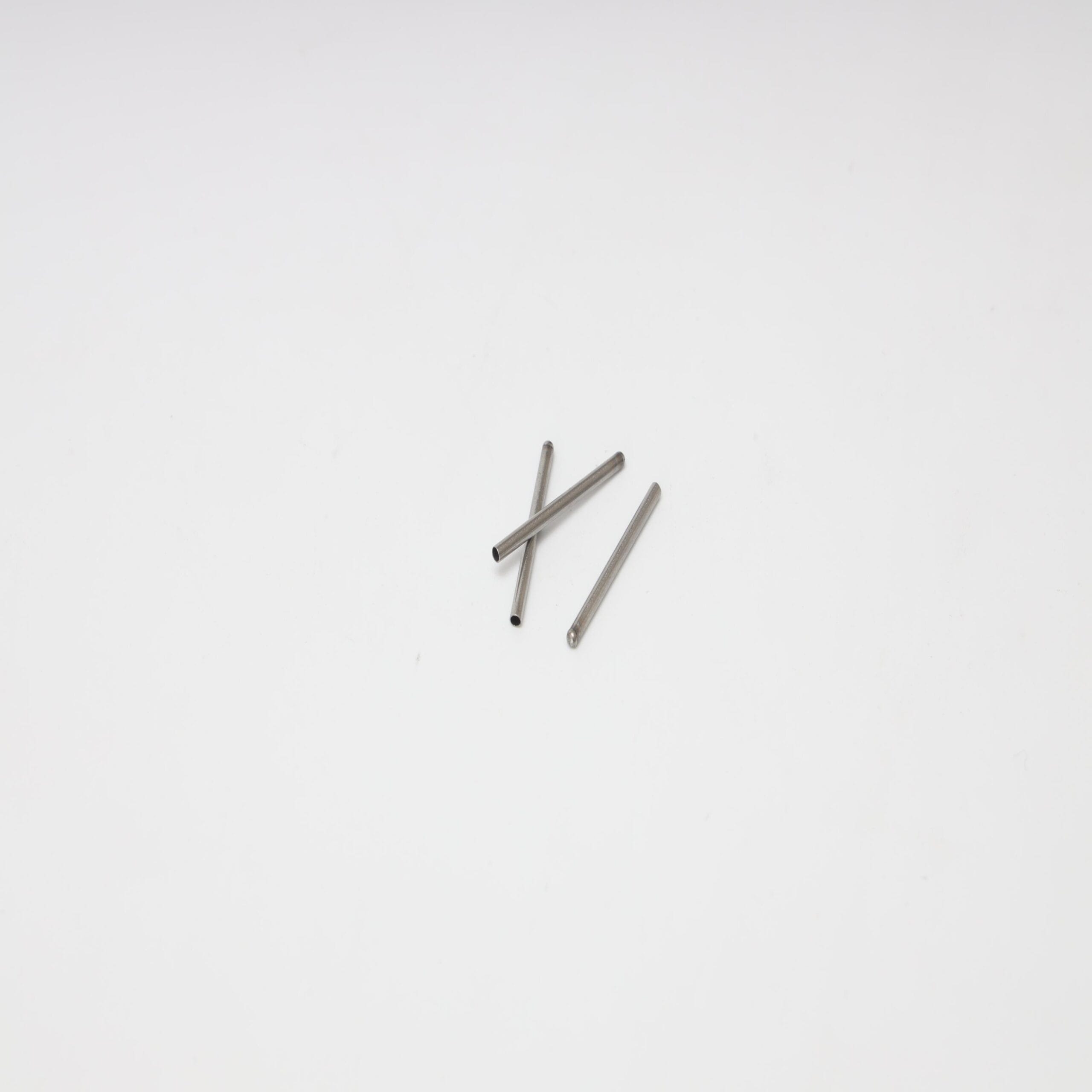

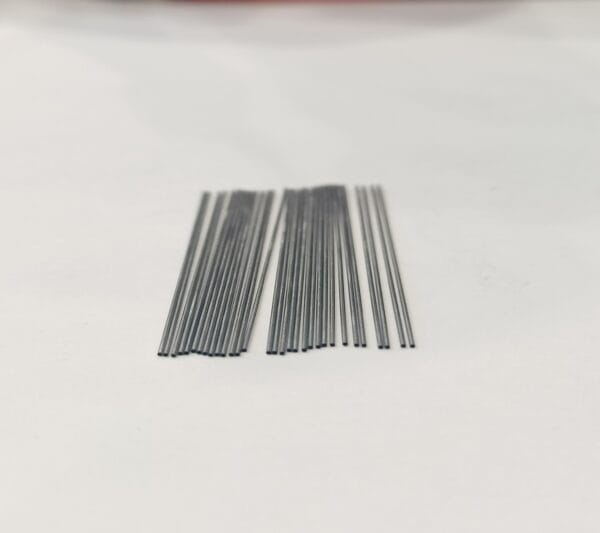

Confluent Nitinol Tube: Durable Material for Minimally Invasive Devices

Advanced Material for Medical Applications

The Confluent Nitinol Tube features a nickel-titanium alloy prized for its unique superelasticity and shape memory. This material provides exceptional flexibility and strength, enabling the tube to bend and twist repeatedly without permanent deformation. It also meets strict biocompatibility standards, making it safe for long-term contact with human tissue.

Surface Treatments to Enhance Performance

Moreover, the tube undergoes precision surface treatments such as electropolishing and mechanical polishing. Electropolishing smooths the surface, reducing friction and improving corrosion resistance. Mechanical polishing, on the other hand, offers a balanced texture for applications requiring extra grip. These options allow customization to suit various medical device needs.

Versatile Diameter Range for Various Uses

Available in diameters from 0.5 mm to 5.0 mm, the tube supports many clinical applications. Ultra-thin sizes (0.5–1.0 mm) work well for neurovascular procedures. Mid-range sizes (1.5–3.0 mm) are ideal for cardiovascular devices like stents and guidewires. Larger diameters (3.5–5.0 mm) fit orthopedic and endoscopic tools. Custom sizes can be made for specialized uses.

Why Choose This Tube?

Its excellent fatigue resistance and flexibility ensure reliability during complex procedures. Additionally, production follows ISO 13485-certified standards for quality and safety. Fast turnaround times and expert support help manufacturers bring devices to market efficiently.

Reviews

There are no reviews yet.