Medical Nitinol Rod — Premium Quality Nickel-Titanium Alloy Rod for Medical Applications

Material and Properties of Nitinol Rod

Our Medical Nitinol Rod is made from premium-grade nitinol, a nickel-titanium alloy renowned for its outstanding superelastic properties and remarkable shape memory capabilities.This unique material bends effortlessly and returns to its original form under stress, making it indispensable in various medical instruments. Nitinol also boasts outstanding biocompatibility, ensuring it is safe and reliable for use inside the human body.

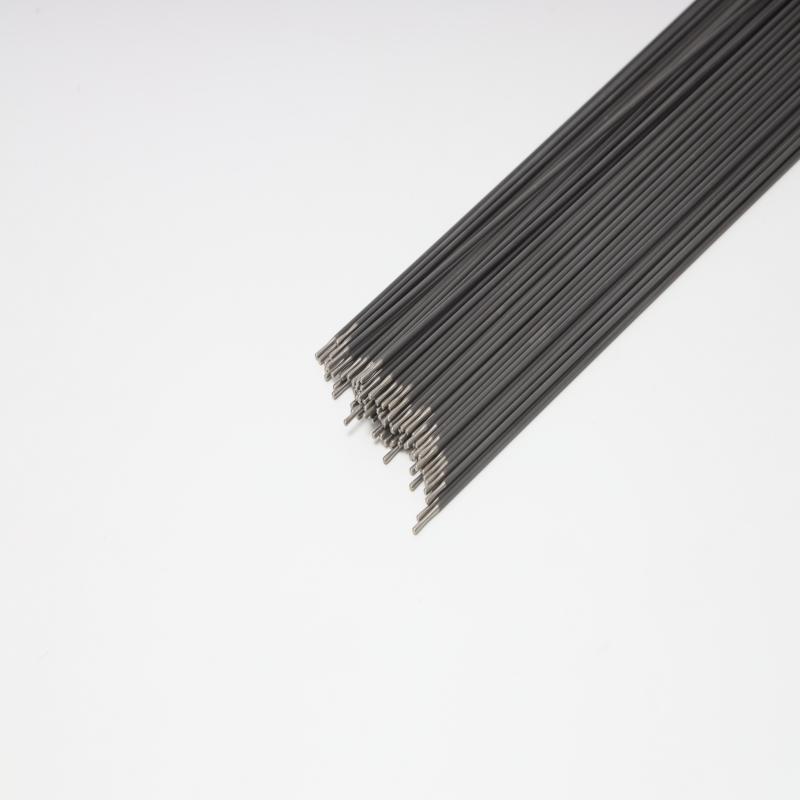

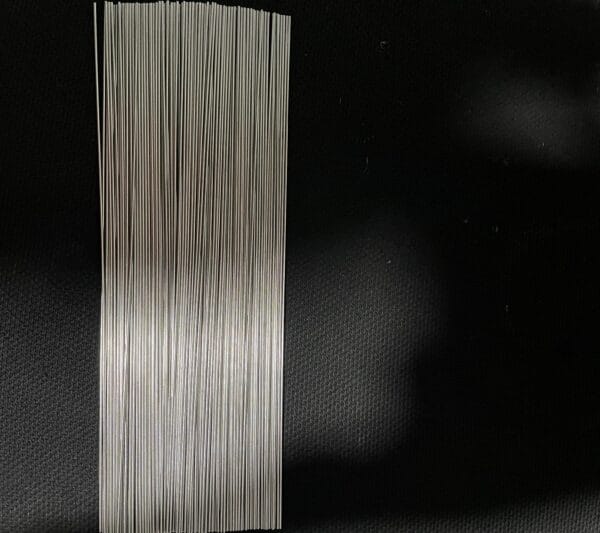

Advanced Surface Finish Options for Nitinol Rod

To maximize performance and longevity, our nitinol rods undergo advanced surface treatments. Choose from electropolishing, which delivers a smooth, contamination-free finish, or mechanical polishing for specific texture requirements. These surface finishes reduce friction, enhance corrosion resistance, and inhibit bacterial adhesion, meeting stringent medical hygiene standards. Custom surface finishes are also available to suit specialized medical device demands.

Diameter Range and Customization of Medical Nitinol Rod

Our medical nitinol rods provide a diverse diameter selection spanning 0.1 mm to 10 mm. Ultra-thin options (0.1–2 mm) cater to delicate medical tools like guidewires, where precision matters most. For stents, orthopedic implants, and surgical instruments, thicker variants (2–10 mm) deliver the strength and durability needed. We tailor rod dimensions using advanced manufacturing techniques to meet your exact requirements.

Key Applications of Medical Nitinol Rod

Guidewires: Highly flexible and kink-resistant for navigating complex vascular pathways.

Stents: Benefit from nitinol’s shape memory for easy insertion and accurate arterial expansion.

Dental Archwires: Apply consistent, gentle pressure to align teeth effectively.

Surgical Instruments: Used in biopsy needles and endoscopy components for durability and reliability.

Orthopedic Implants: Provide stabilization and support natural bone movement.

Why Choose Our Medical Nitinol Rod?

Rigorous Quality Control

Each nitinol rod undergoes comprehensive testing for tensile strength, flexibility, and biocompatibility. We rigorously comply with ISO 13485 and ASTM F2063 standards for medical device materials, ensuring reliable and safe performance every time.

Tailored Custom Solutions

We offer flexible options to modify alloy composition, rod diameter, and surface finish, accelerating your product development cycle with rapid prototyping and personalized service.

Reliable and Consistent Performance

Our nitinol rods maintain superior mechanical and shape memory properties under extreme temperatures and repeated stresses, reducing the risk of device failure.

Fast Global Delivery

Leveraging efficient manufacturing and logistics, we ensure prompt delivery worldwide, even for urgent medical projects.

Expert Technical Support

Our experienced team provides guidance on material selection, design optimization, and testing protocols to help you overcome challenges and enhance your medical devices.

Reviews

There are no reviews yet.