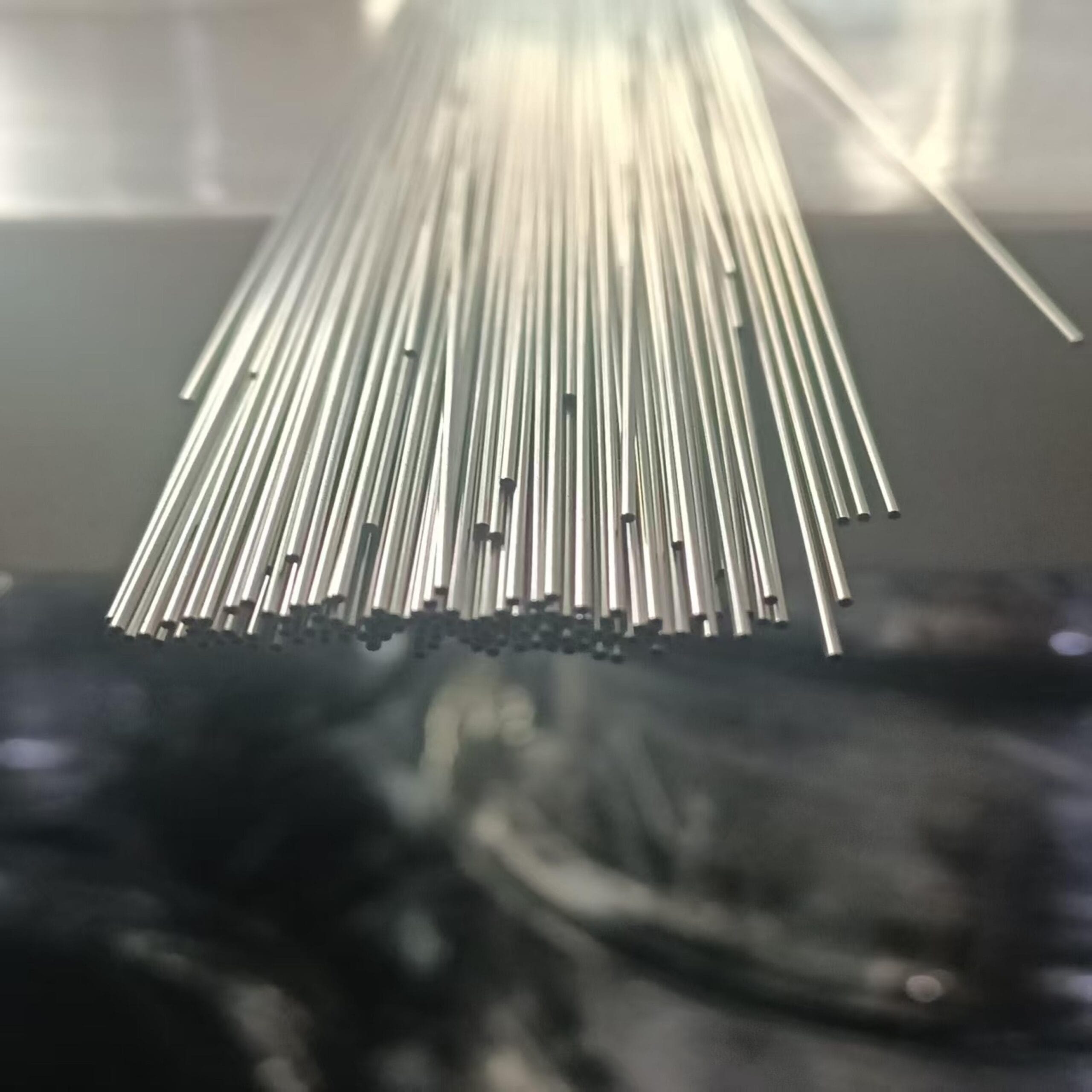

Laser Cut Nitinol Tubing: Precision You Can Rely On

Our nitinol tubing is the foundation of breakthrough technologies across both medical and industrial sectors. Known for its remarkable superelasticity and shape memory, this advanced material supports innovation in stents, surgical tools, actuators, and more. Our semi-finished nitinol tubes are crafted with accuracy, consistency, and performance in mind—ready for your final fabrication step.

Premium-Grade Laser Cut Nitinol for Demanding Applications

We source only medical-grade and engineering-grade nitinol—a Nickel Titanium alloy—ensuring stable performance and high durability. This superior material offers:

Excellent superelastic recovery, ideal for components under mechanical stress

Reliable shape memory effect, returning to a pre-set form when triggered

Exceptional corrosion resistance, perfect for harsh or internal environments

Biocompatibility certified for long-term medical implant use

Full traceability with material certifications from trusted suppliers

Advanced Surface Finishes for Every Application

To meet your technical requirements, we provide a range of finishing options for our laser cut nitinol tubes:

As-Cut Finish – Clean laser-cut edges with minimal heat-affected zones

Mechanical Polishing – Uniform matte surface with reduced micro-roughness

Electropolishing – An exceptionally smooth finish that enhances biocompatibility and minimizes surface friction.”

Titanium Oxide Layer – Optional oxide surface for added corrosion protection and aesthetics

Whether your application demands precision or polish—or both—we deliver exactly what you need.

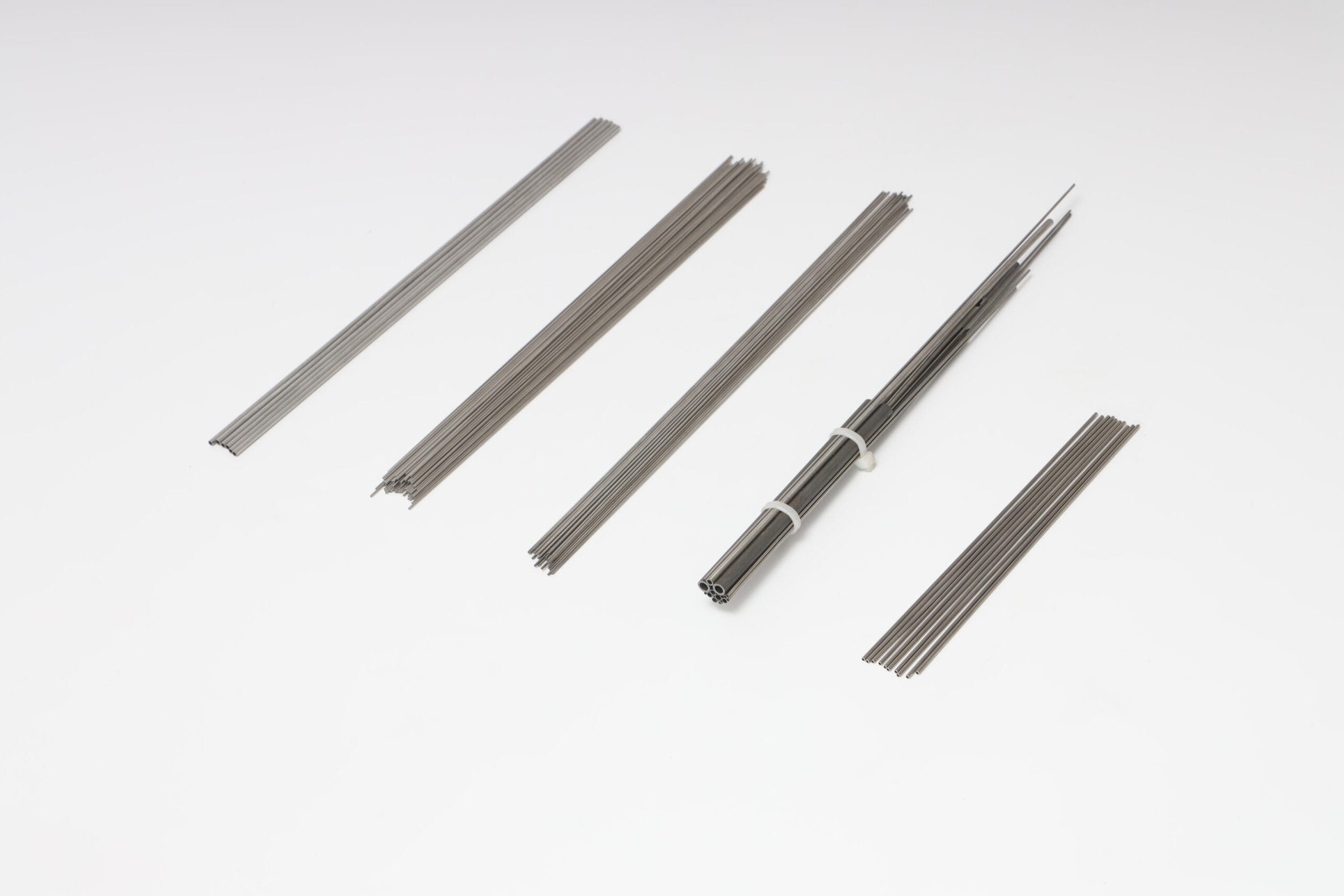

Flexible Sizes for Medical and Industrial Systems

Our laser cut nitinol tubing comes in a wide range of diameters and wall thicknesses, covering:

Micro-diameters – Ideal for catheters, guidewires, and micro-surgical tools

Standard diameters – Used in stents, actuation mechanisms, and surgical delivery systems

Large formats – For industrial actuators, aerospace sensors, and energy equipment

We offer both imperial and metric dimensions, and our manufacturing process maintains tight tolerances for consistent quality, batch after batch.

Laser Cut Nitinol Tubing Applications

Medical Devices & Implants

Vascular Stents – Semi-finished tubes for coronary, peripheral, and neurovascular stents

Minimally Invasive Tools – Guidewires, baskets, graspers, and delivery systems

Orthodontic Archwires – Provide gentle, sustained force for tooth alignment

Orthopedic Devices – Used in staples, bone anchors, and flexible fixation implants

Endoscopy Instruments – Enable flexibility, kink-resistance, and safety in procedures

Engineering, Aerospace, and Energy Applications

Robotics & Actuators – High-precision components with thermal or mechanical activation

Fluid Control Systems – Seals and valves that adapt via shape memory behavior

Aerospace & Defense – Components for vibration damping and reliable actuation

Consumer Electronics – Found in foldable devices, wearables, and eyeglass frames

Energy Industry – Thermal management and downhole oilfield tools

Why Choose Our Laser Cut Nitinol Tubing?

✅ Specialized Expertise – We focus solely on laser cut nitinol and its processing

✅ Precision Laser Technology – Intricate geometries, fine kerf width, and clean cuts

✅ ISO 13485 Compliance – Comprehensive quality assurance compliant with medical-grade requirements

✅ Material Integrity Protection – Laser parameters tuned to preserve shape memory and superelasticity

✅ Surface Finish Flexibility – Tailored to performance and regulatory needs

✅ Reliable Delivery – In-stock availability and scalable production

✅ Collaborative Engineering Support – Optimize your design with our input

Let Laser Cut Nitinol Power Your Innovation

Invest in material performance. Invest in production precision.

Request a quote today or connect with our engineering team to start your custom laser cut nitinol tubing project.

Reviews

There are no reviews yet.