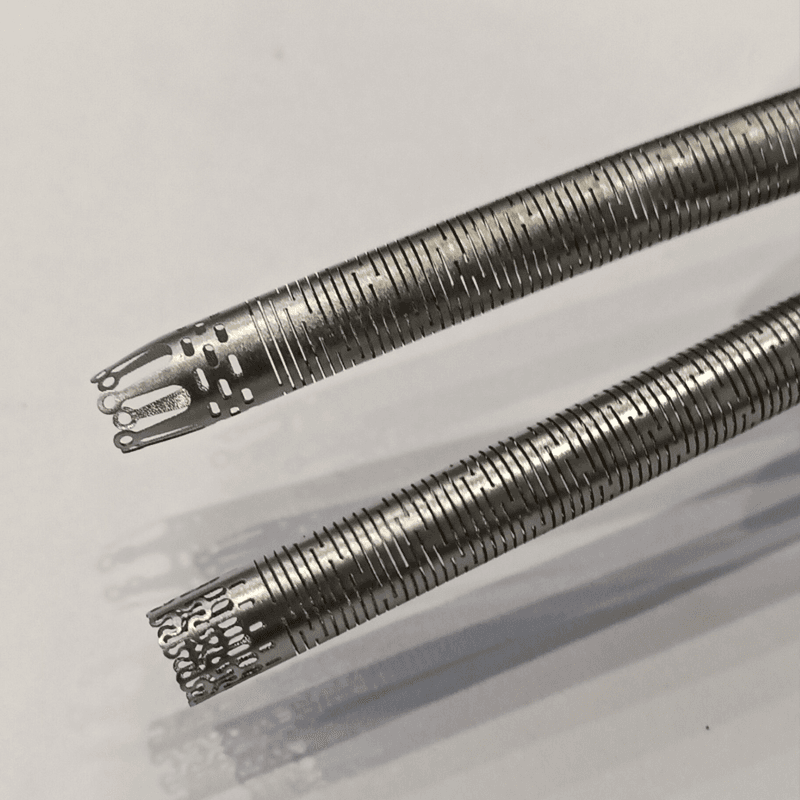

Laser Cut Nitinol Tube for Medical Catheters – Precision and Customization

Our laser cut nitinol tube solutions provide medical device developers with unmatched precision, flexibility, and durability. Made from medical-grade nickel titanium alloy, these tubes offer superelasticity, shape memory, and excellent biocompatibility. They return to their original form after bending and withstand harsh physiological environments—making them ideal for catheter shafts, stent delivery systems, and implantable components.

Medical-Grade Nitinol Tubing You Can Trust

We use high-purity nickel titanium (Nitinol) for all tubes. This smart alloy delivers unique mechanical properties: it flexes without permanent deformation and naturally reshapes with body heat. Our laser cut nitinol tubes resist corrosion from bodily fluids, making them suitable for both short- and long-term implantation.

Surface Finishing Options

Our advanced polishing techniques improve performance and safety:

Electrolytic polishing: Produces ultra-smooth surfaces that reduce friction, ideal for vascular and long-term devices.

Mechanical polishing: Offers a consistent finish suited to disposable or short-use applications.

Both methods ensure clean edges and defect-free surfaces.

Diameter Range and Custom Sizes

We produce laser cut nitinol tubes with diameters ranging from 0.1 mm to 5.0 mm, ideal for applications such as:

Micro-catheters for delicate procedures like neurovascular navigation

Stent delivery tubes requiring radial strength

Orthodontic and orthopedic systems

Custom diameters and wall thicknesses are available for unique application needs.

Applications of Laser Cut Nitinol Tube

These tubes play key roles in a variety of medical devices:

Catheters: Easily traverse vessels while maintaining flexibility and resisting kinks.

Stent delivery systems: Support controlled deployment

Guidewires: Combine precision with directional control

Endoscopic tools: Enable bendability in minimally invasive surgery

Implantable electronics: Withstand movement and temperature changes

Orthodontic devices: Deliver sustained pressure over time

Why Choose Our Laser Cut Nitinol Tubes?

🔬 High-Precision Fiber Laser Cutting

Our cutting systems use fiber lasers to achieve micron-level detail without heat-affected zones. Ideal for prototyping or high-volume manufacturing, this process supports patterns, slots, spirals, and intricate geometries.

⚙️ Custom Manufacturing

Specify your own lengths, shapes, and cut profiles. Our engineers optimize every aspect—from gas flow to cutting speed—for peak manufacturability and quality.

📊 Rigorous Quality Assurance

We comply with ISO 13485 and ASTM F2063 standards and conduct the following quality checks:

Dimensional checks

Mechanical testing

Surface inspection for cracks or burrs

Full material traceability with Certificates of Compliance

🚀 Fast Turnaround, Global Shipping

Most orders ship within 5 business days. Sterile packaging and worldwide logistics supported.

🌱 Eco-Friendly and Cost-Efficient

Laser cutting is tool-free, reducing setup time and cost. We recycle nitinol scrap and use energy-efficient lasers to cut down on carbon footprint.

Partner with Us for Laser Cut Nitinol Tube Excellence

From flexible guidewires to custom catheter shafts, our laser cut nitinol tubes meet the needs of today’s most advanced medical devices. Count on our expertise, fast delivery, and precision to bring your project to life.

👉Send an inqiry to us and share CAD files.

Reviews

There are no reviews yet.