Unlocking Smart Thermal Control with Nitinol Springs

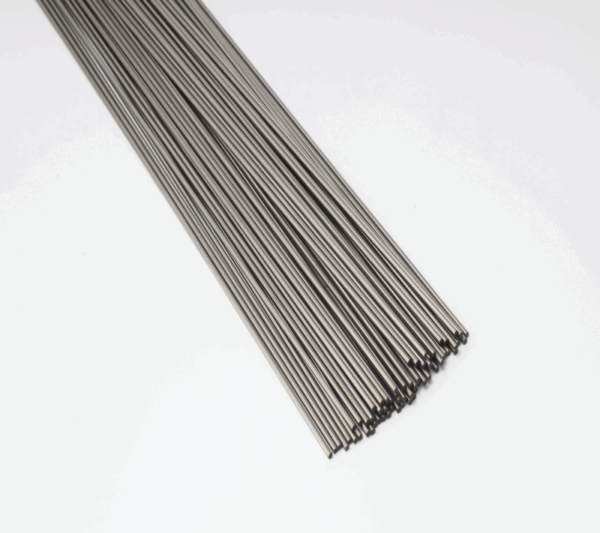

Nitinol Spring: A Modern Solution for Precision Engineering

Thermal control systems have evolved dramatically, and nitinol springs are leading that transformation. Unlike outdated methods like wax-based actuators or mechanical bellows, nitinol spring technology offers fast, repeatable, and leak-proof temperature response. This innovation helps industries achieve both reliability and energy efficiency from the start.

What Makes Nitinol Springs Superior?

1. Leak-Free Functionality and Long-Term Reliability

Conventional wax and bellow systems can leak or wear down over time. In contrast, nitinol springs operate through solid-state transformation, completely eliminating the risk of leaks. Therefore, they’re an ideal choice for chemical valves, medical devices, and high-stakes mechanical systems.

2. Faster Thermal Response Than Traditional Materials

Nitinol reacts 2–3 times faster to heat changes than wax. As a result, it provides real-time thermal regulation in systems like smart HVAC units, aerospace sensors, and electronic safety components.

3. Consistent Performance with Direct Heat Transfer

Because nitinol spring elements contact the heat source directly, they reduce delays caused by insulating layers. Moreover, this results in more consistent control and improved energy use.

4. Economical for Both Mass and Custom Applications

Thanks to scalable production methods, nitinol spring designs are now cost-effective. Whether you’re developing high-volume consumer products or custom-engineered solutions like 0.2 mm micro springs, the material fits a wide range of budgets.

One-Way vs. Two-Way Nitinol Springs

One-Way Nitinol Spring Mechanisms

One-way springs return to their original shape when heated above the Austenite finish (Af) temperature. They are commonly used in safety valves, single-use surgical tools, and heat-triggered latches. Once they move, they stay in position until replaced or reset manually.

Two-Way Nitinol Springs: Reversible and Repeatable

Two-way nitinol springs go further. They change shape when heated and return to their original form as they cool. This makes them ideal for robotic arms, temperature-controlled vents, and automated devices that need continuous cycling.

Applications of Nitinol Springs in Modern Industries

Aerospace and Aviation

In aircraft, nitinol springs reduce weight and deliver more cycles than traditional parts. They control fuel valves, airflow systems, and emergency equipment, ensuring high performance under stress.

Medical and Biomedical Devices

With excellent biocompatibility, these springs are used in stents, catheters, and surgical tools. In addition, their ability to change shape makes them perfect for minimally invasive devices that operate inside the human body.

Smart Homes and Consumer Products

Nitinol-based solutions appear in kitchen faucets, HVAC dampers, and fire safety products. Because of their responsiveness and efficiency, they help users save both energy and cost.

Construction and Infrastructure

In civil engineering, nitinol spring components help protect structures against earthquakes. When built into foundations or frames, they absorb and release seismic energy to reduce damage.

Conclusion: The Future Is Built with Nitinol Springs

As technology demands smarter materials, nitinol springs have proven they’re more than a niche solution. They offer durability, precision, and flexibility across many sectors. More importantly, they continue to get more affordable, making them accessible to both startups and large-scale manufacturers.

For any application where temperature matters, a nitinol spring might just be your smartest investment yet.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

Reviews

There are no reviews yet.