Precision Cutting Nitinol Wire for Superior Performance and Reliability

Material: Premium Nitinol Alloy for Strength and Flexibility

Our cutting nitinol wire is manufactured using premium nickel-titanium alloy (Nitinol), celebrated for its outstanding superelasticity and shape memory properties. This material provides excellent strength, resistance to corrosion, and reliable performance even under extreme temperatures and frequent mechanical stress. Consequently, it is perfectly suited for use in medical, aerospace, and industrial fields. Because of these qualities, our nitinol wire ensures dependable durability in the most challenging conditions.

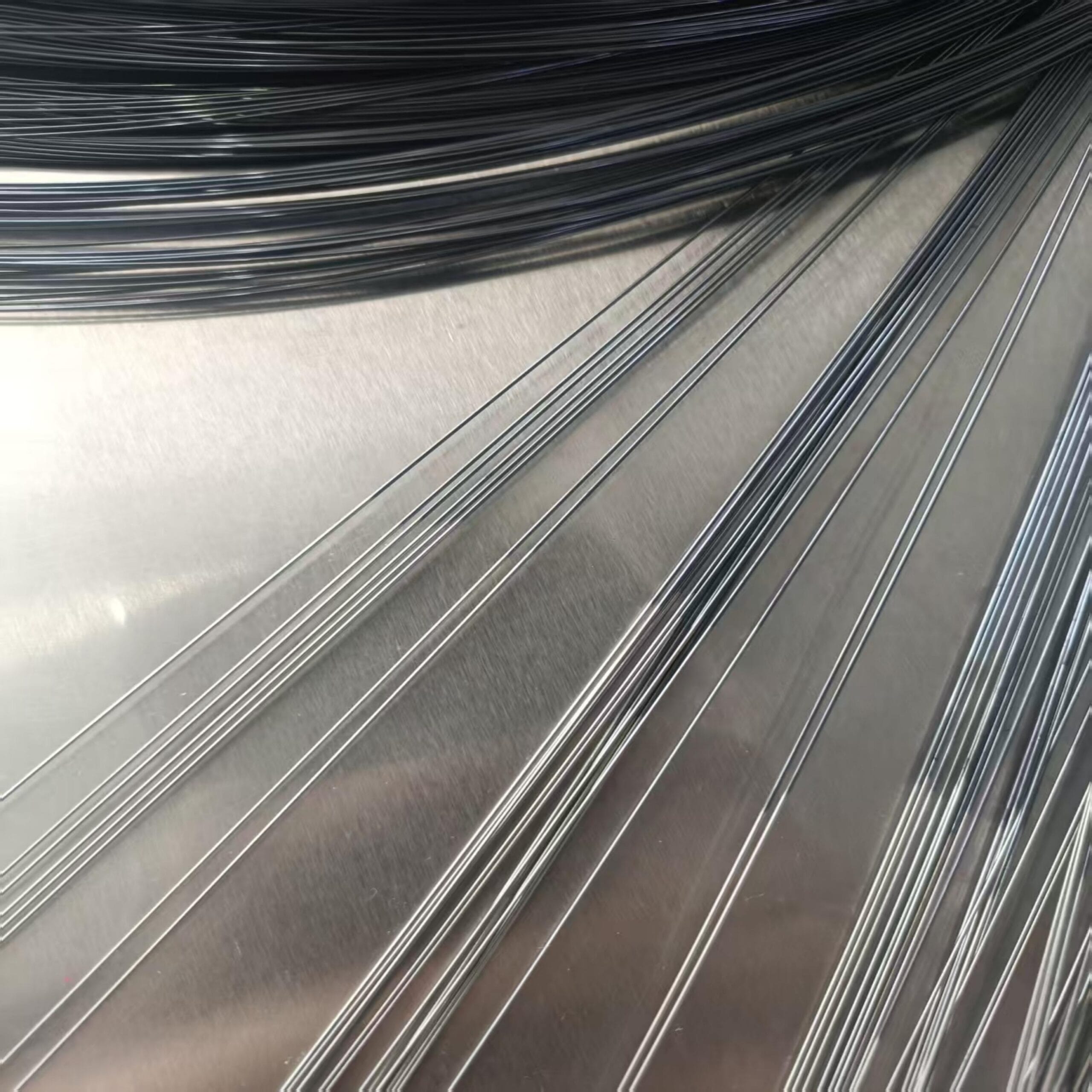

Surface Finish: Ultra-Smooth Ra ≤0.2μm for Optimal Cutting Efficiency

Each cutting nitinol wire undergoes state-of-the-art precision grinding and polishing to achieve an ultra-smooth surface roughness of Ra ≤0.2μm. This refined finish minimizes friction, which reduces tissue damage in medical procedures and enhances the lifespan of cutting tools. Moreover, advanced grinding removes microscopic imperfections, ensuring a uniform surface that prevents debris buildup. Consequently, the wire maintains consistent performance in delicate applications such as cardiovascular surgery or precision electronics manufacturing.

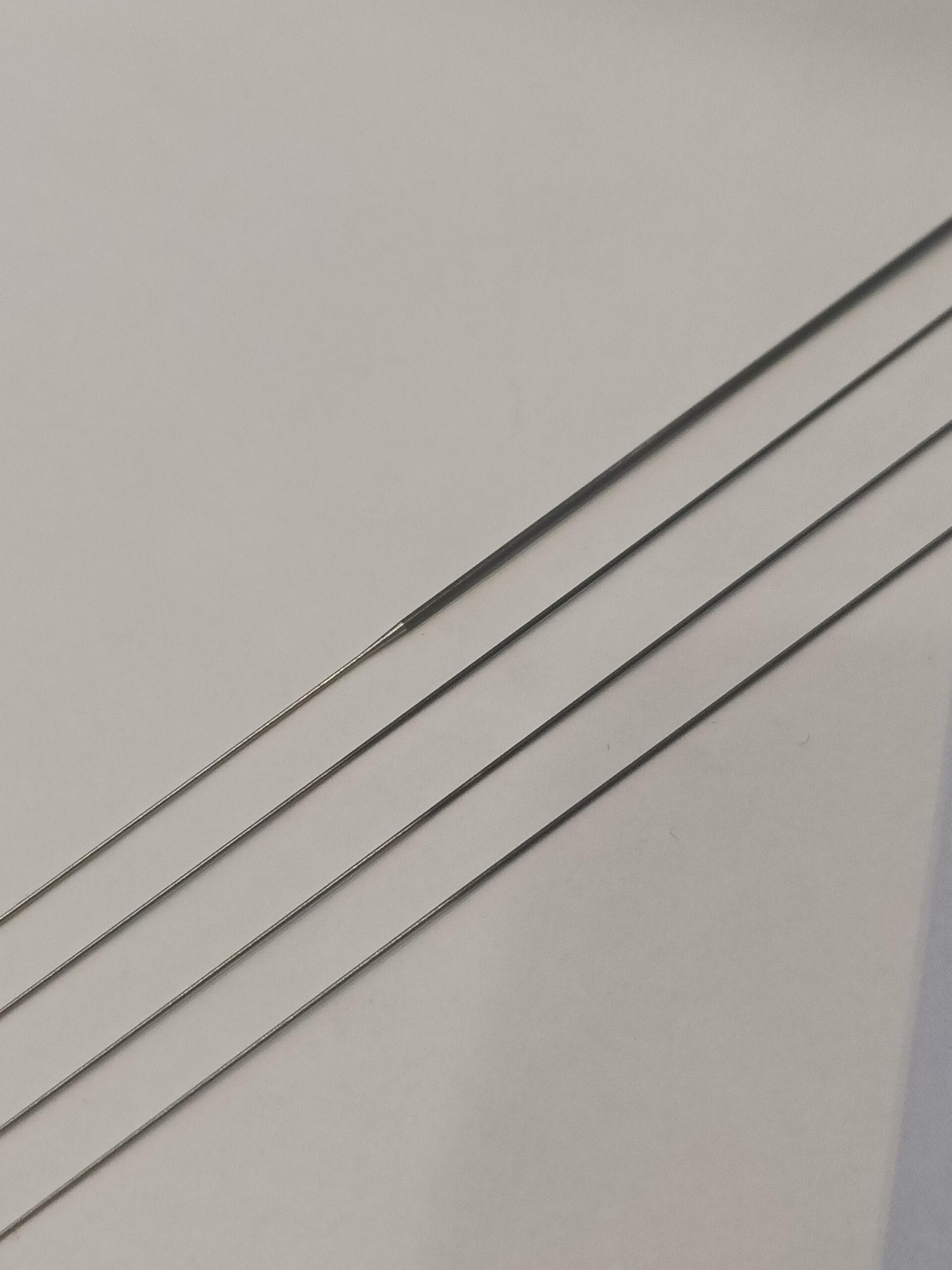

Diameter Range: Custom Sizes from 0.1mm to 2.0mm

We offer cutting nitinol wire in a broad diameter range, from ultra-fine 0.1mm wires for micro-scale medical devices (e.g., stents, catheter guides) to robust 2.0mm wires suitable for aerospace actuators and industrial cutting tools. Intermediate diameters (0.5mm–1.2mm) are ideal for orthodontic archwires and robotic components. Additionally, custom diameter options are available to meet specialized project requirements.

Applications: Versatile Cutting Nitinol Wire for Multiple Industries

Medical Devices: Minimally invasive surgical tools, orthodontic braces, neurovascular intervention systems.

Electronics: Precision cutting of circuit boards, micro-springs for sensors and connectors.

Aerospace & Industrial: Actuators for valves, robotic parts, high-precision composite cutting tools.

Why Choose Our Cutting Nitinol Wire?

Consistent Quality: Strict quality control ensures uniform dimensions, mechanical properties, and surface finish conforming to ASTM F2063 standards.

Advanced Manufacturing: Proprietary grinding combined with electrochemical polishing achieves Ra ≤0.2μm without compromising wire strength.

Customization: Tailor diameters, surface coatings (PTFE, silicone), or pre-cut lengths to fit your workflow.

Reliability: Tested for extreme conditions from -50°C to 150°C; corrosion resistance ensures safe use in MRI, chemical plants, and space applications.

Expert Support: Engineering assistance for material selection, testing, and troubleshooting maximizes your project success.

Optimized for Precision and Durability

Our cutting nitinol wire is engineered for precision, fatigue resistance, and versatility. The ultra-smooth surface reduces wear on cutting instruments, while the fatigue-resistant alloy supports millions of operational cycles. Thus, whether manufacturing life-saving medical devices or cutting-edge aerospace components, this wire delivers the accuracy and reliability required by modern industries.

Order Today with Confidence

Request samples to evaluate performance in your application. Furthermore, volume discounts and expedited shipping help keep your projects on track. Contact us now to discuss your requirements or request a quote.

Reviews

There are no reviews yet.