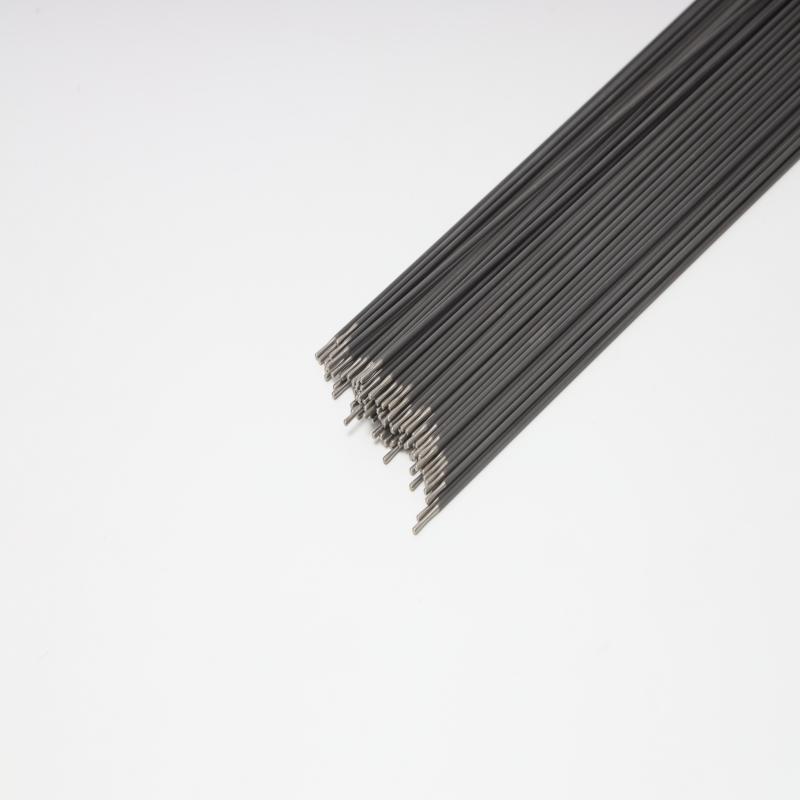

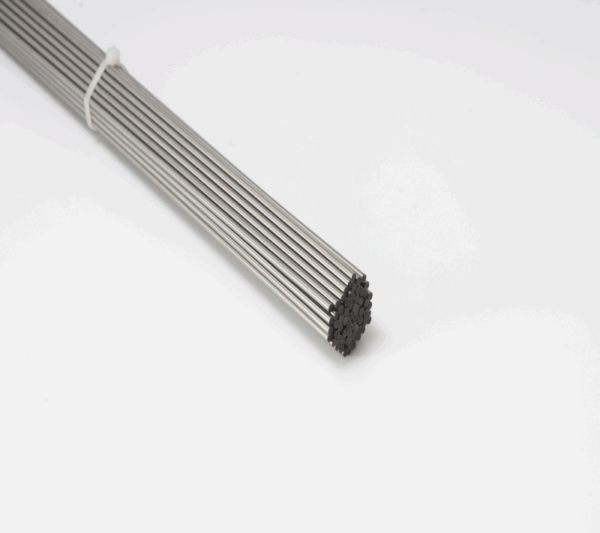

Precision Engineered Customized Nitinol Rods for Your Unique Applications

Our factory specializes in manufacturing high-quality customized nitinol rods designed precisely to meet your unique specifications. Combining advanced nickel-titanium alloy expertise with innovative engineering, we deliver reliable, high-performance rods suited for diverse industries and demanding environments.

Premium Materials: Superior Quality Customized Nitinol Rods

We use only certified nickel-titanium (nitinol) alloy to produce every customized nitinol rod. Known for its remarkable superelasticity, shape memory effect, and excellent wear resistance, nitinol adapts seamlessly to temperature fluctuations, making it ideal for dynamic, high-stress applications. Our strict raw material selection ensures consistent strength, durability, and long-term functionality across all batches.

Tailored Surface Finishes to Match Your Application

Choose from a variety of surface finishes on your customized nitinol rod to optimize performance. Options include ultra-smooth polished surfaces for medical instruments requiring minimal friction, lightly textured finishes for improved mechanical grip, or specialized coatings enhancing corrosion resistance. Each rod undergoes rigorous quality control to guarantee flawless surface integrity.

Wide Diameter Range and Precise Dimension Control

Our customized nitinol rods are available in diameters ranging from 0.1 mm up to 25 mm, catering to applications from delicate microsensors to robust aerospace components. We maintain tight manufacturing tolerances (±0.01 mm) to ensure exact sizing for critical projects. Whether ultra-thin or heavy-duty, our rods meet the most demanding engineering requirements.

Versatile Applications Across Multiple Industries

Customized nitinol rods play vital roles in numerous fields. In healthcare, they form the backbone of flexible, biocompatible surgical tools for minimally invasive procedures. Robotics and automotive industries rely on them for precise actuators, sensors, and valves. Aerospace teams incorporate them in thermal control systems for satellites, while consumer electronics benefit from nitinol’s durability in connectors and springs.

Why Choose Our Customized Nitinol Rod Solutions?

Collaborative Expertise: We partner with you throughout design and production, refining alloy composition, surface treatments, and dimensions.

Rapid Turnaround: Utilizing advanced CNC machining and laser cutting, we fulfill urgent orders without sacrificing quality.

Stringent Quality Testing: Every customized nitinol rod undergoes tensile, fatigue, and thermal response testing to meet strict standards.

Competitive Pricing: Efficient processes and bulk sourcing allow cost-effective solutions for all clients.

Global Shipping & Support: Worldwide delivery combined with expert technical assistance for installation and maintenance.

Get Your Customized Nitinol Rods Today

Whether you require prototypes or large-scale production, our team is dedicated to delivering customized nitinol rods that exceed industry standards. Contact us now to discuss your project, optimize material performance, reduce costs, and accelerate innovation.

Reviews

There are no reviews yet.