Nitinol Tube Cutting: Precision Solutions for Demanding Applications

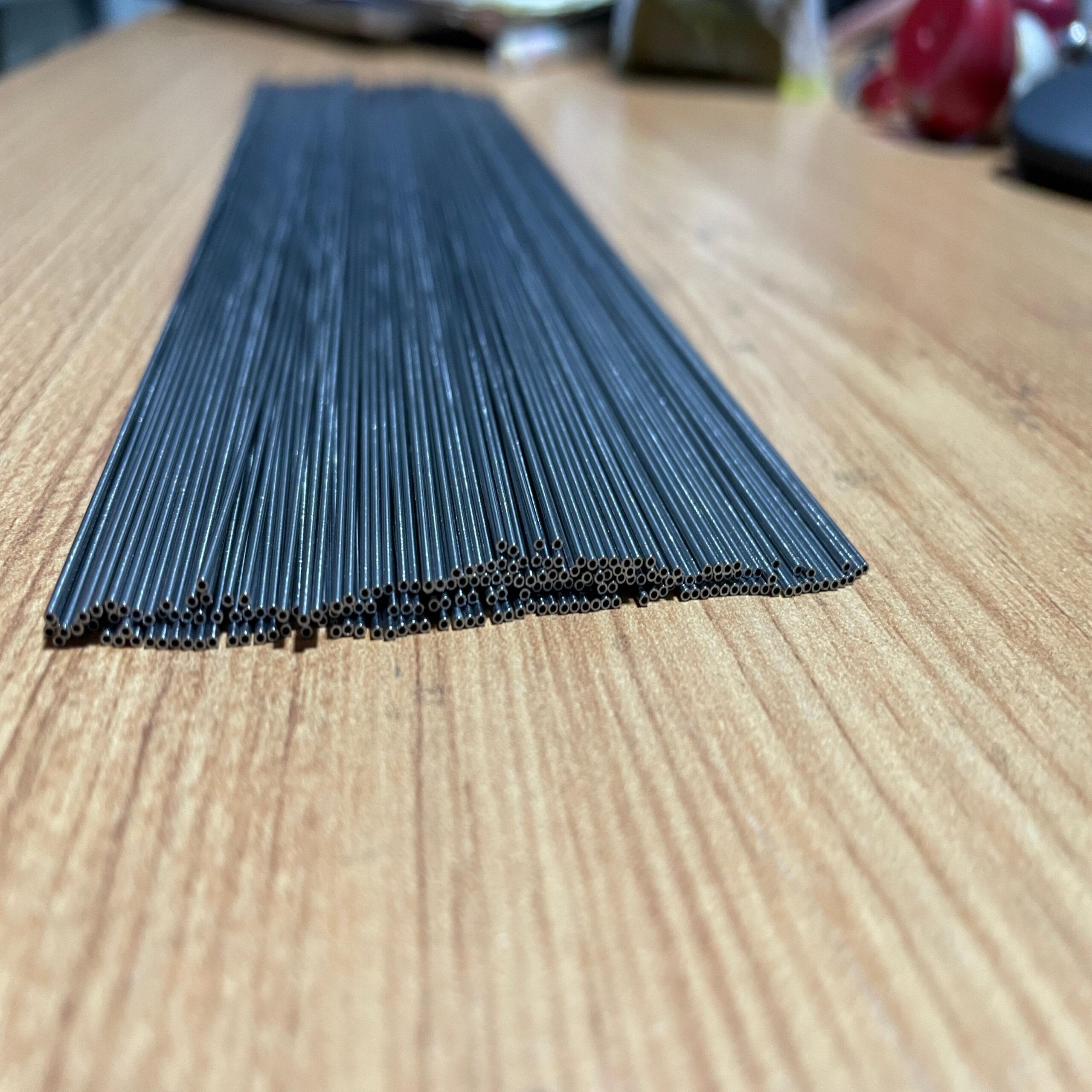

Introducing Our Nitinol Tube Cutting Expertise

Looking for reliable nitinol tube cutting services tailored to complex and critical environments? Our team delivers high-performance solutions using premium nickel-titanium alloy. With a unique phase transition range of -10°C to +50°C, our nitinol tubing guarantees consistent performance across medical, aerospace, and industrial applications. Thanks to its shape memory and superelastic properties, it adapts smoothly to extreme operating conditions.

Engineered for Quality and Customization

Material Benefits

We use top-grade nitinol alloy to produce tubes with predictable transformation behavior. This guarantees stable performance, even during temperature swings. Because of our precise material formulation, our nitinol tube cutting supports sensitive use cases without compromising integrity.

Surface Finishing Options

Every tube receives a polished, uniform surface finish. This reduces friction and enhances corrosion resistance—key for applications like surgical implants. Additionally, electropolishing or oxide coatings are available to increase biocompatibility and strength.

Flexible Diameter Range

Choose from outer diameters between 0.1 mm and 10 mm, or request custom sizing. With our laser and EDM tube cutting systems, we achieve tight tolerances (±0.05 mm) and burr-free edges, ideal for high-precision assemblies.

Applications Across Industries

Medical Devices

From stents and guidewires to surgical instruments, our tubing flexes within the human body and performs reliably under sterilization and MRI conditions.

Aerospace Components

Design sensors, actuators, and vibration-control mechanisms that withstand rapid temperature changes while remaining lightweight.

Industrial Systems

Integrate our tubing into smart robotic joints, self-adjusting valves, and flexible fluid transfer components that respond to mechanical stress.

Consumer Electronics

Enable cutting-edge wearable tech, eyeglass frames, and micro-actuators that recover their shape in real time.

Why Our Nitinol Tube Cutting Stands Out

Precise Phase Control: Tunable transition temperatures between -10°C and +50°C

Medical-Grade Standards: ASTM F2063 certification ensures biocompatibility and reliability

Fast Customization: Prototypes in 5 days; full-volume orders in 3 weeks

Advanced Testing: Non-destructive verification with micro-CT and eddy current methods

Global Support: Multilingual technical assistance across eight languages

Cost Efficiency: Scalable automation allows bulk pricing without sacrificing quality

Get Started Today

Over 300 global companies trust our nitinol tube cutting solutions. Backed by ISO 13485 and AS9100 certifications, we deliver worldwide. Whether you’re prototyping or scaling up, request a free sample or submit your specs—we guarantee a perfect fit.

Reviews

There are no reviews yet.