High-Performance Material: Nickel-Titanium Alloy

Our custom helical tubes are crafted from Nitinol (Nickel-Titanium), an intelligent alloy renowned for its shape memory properties, superelasticity, and exceptional resistance to corrosion. These unique characteristics make Nitinol especially suitable for use in challenging environments that demand both flexibility and mechanical strength.

In addition, the precise ratio of nickel to titanium is optimized to preserve structural integrity and ensure long-lasting performance, making it an ideal choice for mission-critical applications across various industries.

Polished Surface Finish for Enhanced Functionality

To further improve performance, our helical tubes undergo precision grinding and electropolishing.

This process removes surface irregularities, delivering a highly polished and exceptionally smooth finish.

As a result, friction and wear are minimized—critical for medical and fluid-transfer applications. In addition, this finish promotes biocompatibility and seamless integration into sensitive systems.

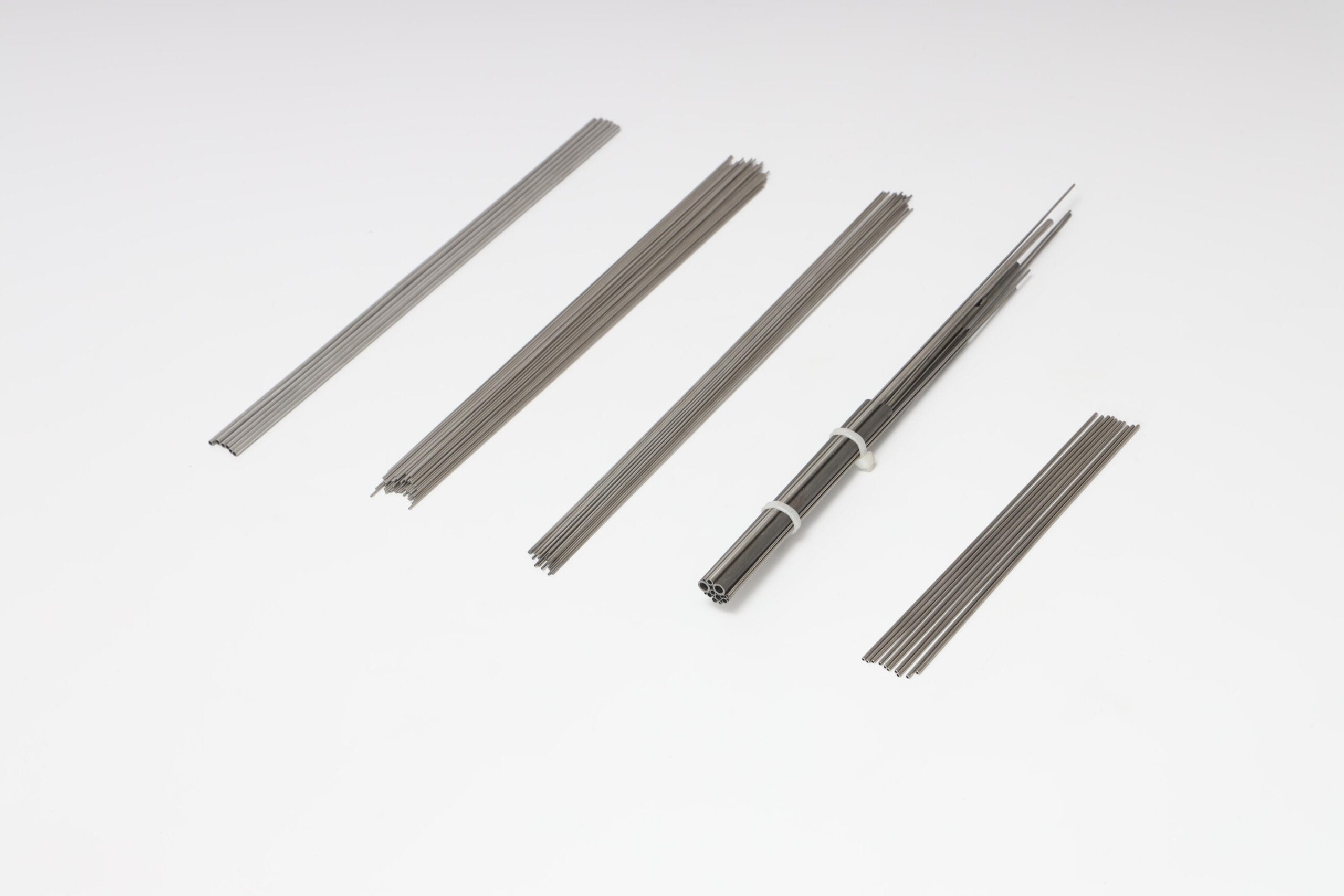

Customizable Diameter Range for Diverse Needs

Thanks to our advanced nitinol tube drawing capabilities, we offer diameters ranging from 0.5 mm to 12 mm, all within strict tolerances of ±0.05 mm.

In addition, we provide rapid prototyping and custom sizing beyond the standard range to meet specialized design requirements or tight development schedules.

Application Versatility Across Industries

Our custom helical Nitinol tubes are suitable for a wide range of uses:

Medical Devices: For example, they’re ideal in guidewires, catheters, and stents, where the helical structure enhances flexibility in complex anatomies.

Industrial Systems: Integrated into actuators or sensors that rely on shape memory for automatic responses.

Aerospace Components: Applied in vibration-resistant mechanisms or high-cycle fatigue assemblies.

Consumer Electronics: Used in space-saving thermal systems or flexible connectors in compact devices.

Why Our Nitinol Tube Drawing Process Stands Out

We combine technical expertise with customization to meet your exact product needs:

Advanced Techniques: Our precise nitinol tube drawing methods maintain material integrity while forming complex helical geometries.

Tailored Designs: You can specify pitch, coil density, and cross-sectional shape to fit your design perfectly.

Fast Delivery: From initial design to finished product, our streamlined process keeps your project on track.

Quality-Driven Manufacturing: Each batch is tested for tensile strength, dimensional accuracy, and cyclic fatigue.

Dedicated Technical Support: Our team offers guidance from concept through integration—ensuring you choose the right specifications and materials.

Key Benefits of Our Helical Nitinol Tubes

Choosing our solution offers several advantages:

Superelasticity: Tubes recover their original shape after bending, even under repeated stress.

Lightweight Strength: High strength-to-weight ratio benefits both aerospace and medical fields.

Biocompatibility: Meets ISO 10993 certification requirements, confirming its biocompatibility for medical applications.

Exceptional Durability: Resistant to corrosion from saltwater, bodily fluids, and chemicals—ensuring long service life.

Get in Touch with Our Experts Today

Contact us now to explore our custom helical Nitinol tubes and advanced nitinol tube drawing services. We offer tailored solutions that blend performance, quality, and speed—designed to help your products excel in even the most demanding environments.

Reviews

There are no reviews yet.