Cope Nitinol Mandril Wire Guide for Precision Industrial Applications

Introduction

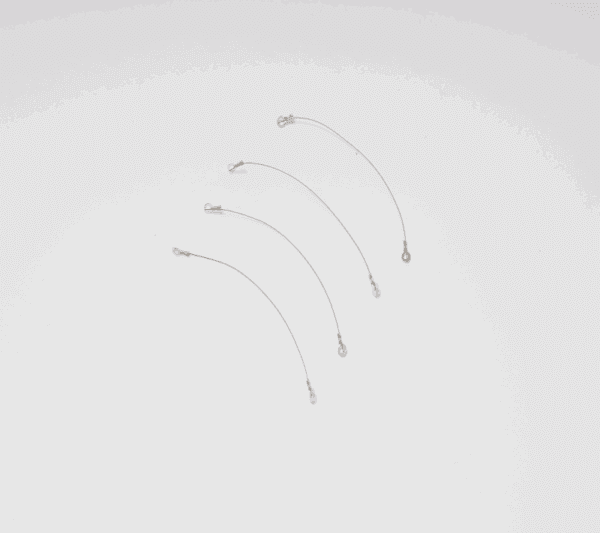

The cope nitinol mandril wire guide is a specialized tool engineered for high-precision applications across medical, aerospace, and industrial sectors. Built from a nickel-titanium alloy, this wire offers an ideal balance of strength, flexibility, and thermal stability. Whether used for guiding catheters or sharpening cutting tools, it ensures consistent performance under stress.

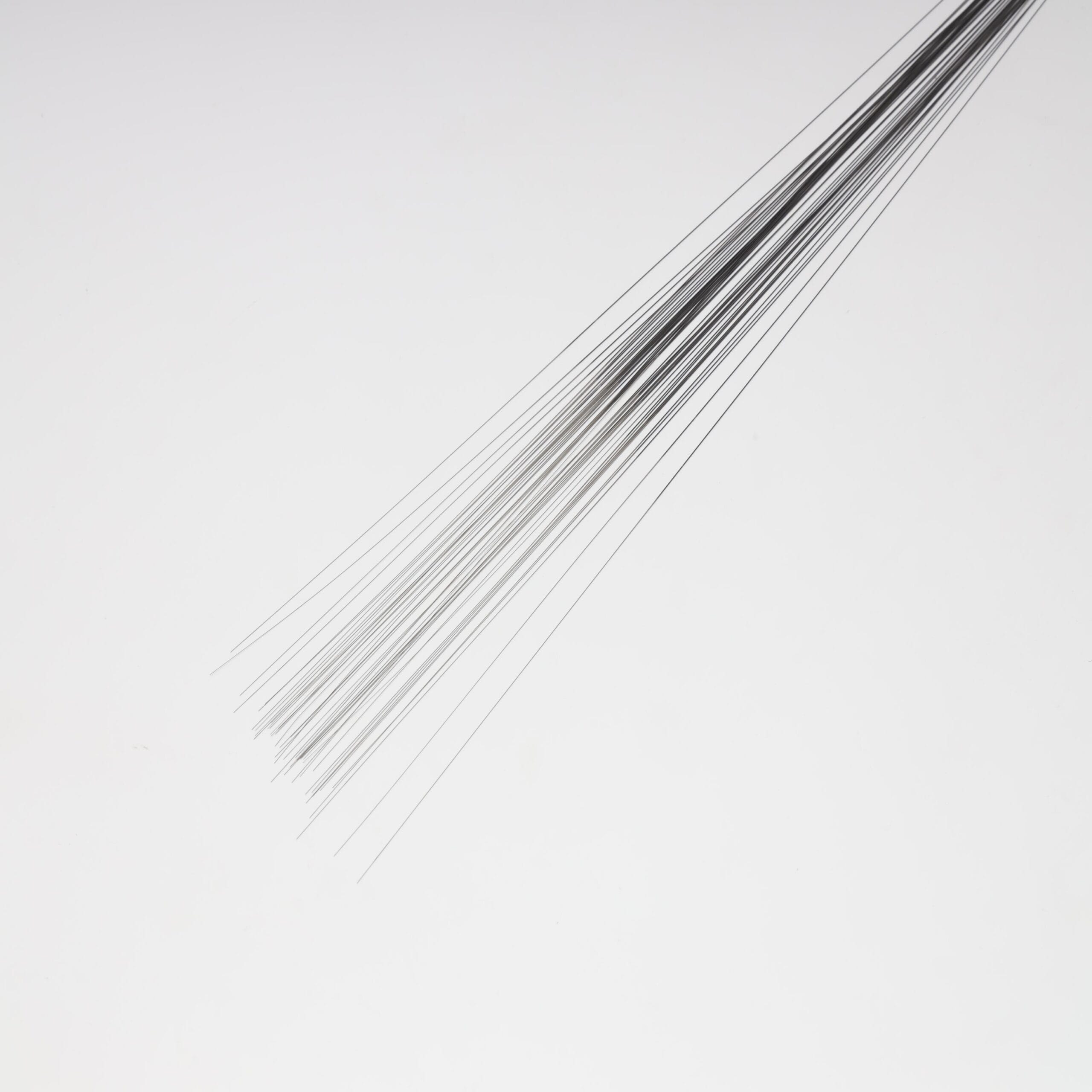

High-Quality Nitinol Construction

Manufactured using premium-grade nitinol wire, this guide exhibits superior superelasticity and shape memory. Its resistance to fatigue and corrosion makes it a reliable solution for both one-time and repeated use. The wire maintains dimensional integrity even in high-vibration or high-temperature environments.

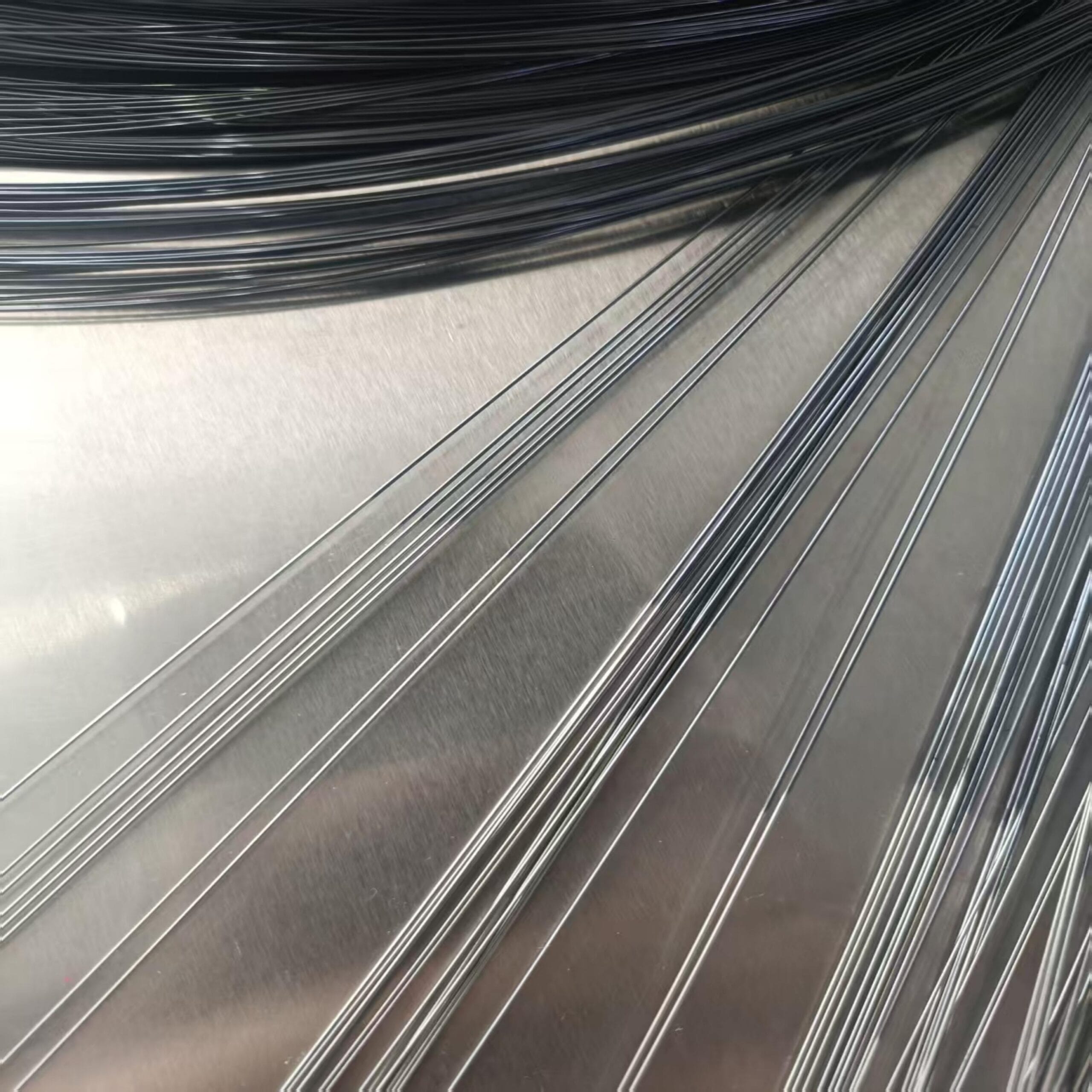

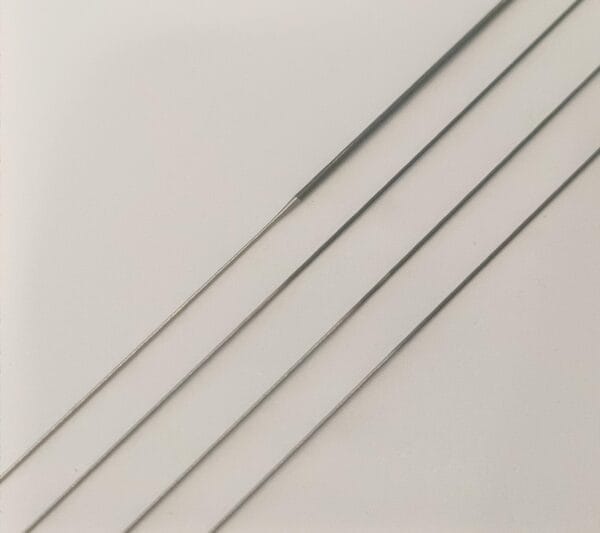

Polished Surface for Smooth Operation

Each mandril wire guide undergoes advanced polishing to deliver a uniform, low-friction finish. This treatment enhances durability and reduces debris accumulation during use. The smooth surface ensures better handling in automated and manual processes alike.

Customizable Diameter Range

We offer diameters from 0.1 mm to 3.0 mm, meeting the needs of micro-scale surgical tools as well as larger industrial equipment. Custom sizing is available upon request, ensuring compatibility with your specific designs and processes.

Core Applications

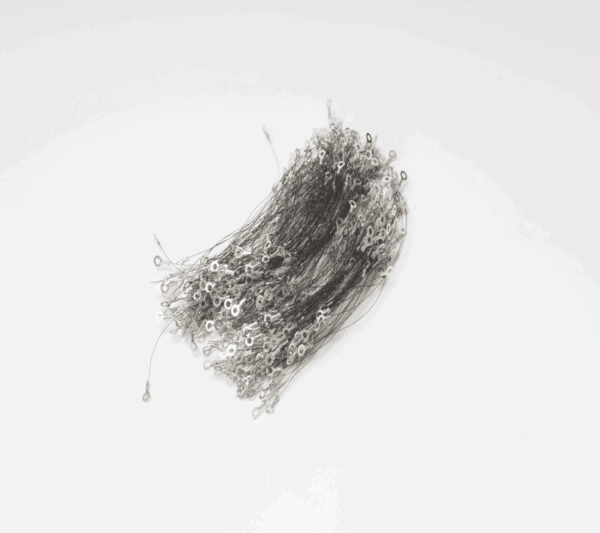

➤ Medical Devices

Used in guidewires, catheter mandrels, and surgical instruments requiring both flexibility and biocompatibility.

➤ Aerospace Components

Supports grinding and shaping precision turbine blades and sensor assemblies.

➤ Automotive Systems

Ideal for fuel injection mechanisms and small-engine parts needing heat resistance.

➤ Electronics and Micro-Manufacturing

Shapes micro-connectors and delicate circuit elements with stable results.

➤ Tooling & Mold Maintenance

Keeps dies, molds, and fine-edged tools sharp and production-ready.

Why Engineers Choose This Nitinol Wire Guide

Reliable Performance: The guide wire resists deformation and breakage under repeated stress.

Ease of Use: Compatible with CNC machines, EDM systems, and handheld tools.

Tight Tolerances: Manufactured to ±0.01 mm for precision work.

Fast Lead Times: Orders shipped in 48 hours with full technical support.

Certified Quality: Meets ISO 13485 and ASTM F2063 standards for medical-grade reliability.

Eco-Conscious: 100% recyclable and produced under low-waste guidelines.

Conclusion

Engineered for versatility and precision, the cope nitinol mandril wire guide empowers manufacturers in multiple industries. Its unique material properties and consistent performance make it a trusted choice for high-stakes applications—from surgical tools to aerospace parts.

Reviews

There are no reviews yet.