Nickel-Titanium Alloy: A Superior Functional Material

Overview

Nickel-Titanium (NiTi) shape memory alloy is a high-performance material distinguished by its unique mechanical and functional characteristics. It exhibits an elongation rate exceeding 20%, a fatigue life of up to 10⁷ cycles, and damping properties approximately ten times greater than conventional metal springs. Moreover, its corrosion resistance surpasses even the highest-grade medical stainless steel, making it an ideal choice for both engineering and medical applications. Beyond its remarkable shape memory behavior, NiTi offers a unique combination of wear resistance, corrosion resistance, high damping capacity, and superelasticity.

Key Properties and Characteristics

1. Phase Transformation Behavior

Formed by combining almost equal parts of nickel and titanium, NiTi is categorized as a binary alloy.It exhibits reversible phase transformations between two primary crystal structures—austenite and martensite—in response to temperature changes and mechanical stress. The typical cooling sequence follows:

Austenite (Parent Phase) → R-Phase (Intermediate) → Martensite (Low-Temperature Phase)

- Austenite Phase: Stable at higher temperatures (above Austenite Finish temperature, Af) or upon stress release. It features a cubic crystal structure, providing high stiffness and dimensional stability.

- Martensite Phase: This phase becomes stable at low temperatures—typically below the Martensite Finish (Mf) point—or when mechanical stress is applied. This phase has a hexagonal crystal structure, offering high ductility and deformability.

- R-Phase: A transitional rhombohedral structure occurring during cooling, between austenite and martensite phases.

2. Unique Functional Properties

Shape Memory Effect (SME)

NiTi can return to its original shape following deformation.When deformed in the martensitic phase (low temperature) and then heated above Af, it returns to its pre-deformation shape due to a thermally-induced phase transformation. Commonly known as the shape memory effect, this behavior enables shape recovery.

Superelasticity (SE)

Also called pseudoelasticity, superelasticity refers to the ability of NiTi to undergo large, recoverable deformations—up to 8% strain—without permanent set. Under stress, austenite transforms into stress-induced martensite, enabling exceptional elasticity without the need for heat. This process results in a flat or plateau-like stress-strain curve during loading and unloading, making it ideal for applications requiring constant forces.

Types of Superelasticity:

- Linear Superelasticity: Stress-strain behavior is nearly linear.

- Nonlinear Superelasticity (True Pseudoelasticity): Involves stress-induced martensite transformation and reverse transformation during unloading.

Note: Superelastic properties degrade at temperatures exceeding 400°C.

Oral Temperature Sensitivity

Unlike stainless steel or cobalt-chromium orthodontic wires, NiTi archwires exhibit force variability with changes in intraoral temperature. As the temperature rises, the force output increases—potentially accelerating tooth movement by enhancing blood flow in compressed tissues. However, this can complicate clinical force control.

Corrosion Resistance

NiTi alloys demonstrate corrosion resistance comparable to or better than stainless steel, thanks to the formation of a stable surface oxide layer.

Biocompatibility and Nickel Safety

Despite containing ~50% nickel (a known carcinogen), NiTi is biocompatible due to a protective titanium oxide surface (TiOx/TiNiOx), which inhibits nickel ion release, making it safe for biomedical use.

Light, Gentle Orthodontic Forces

Compared with stainless steel, NiTi wires generate significantly lighter and more consistent forces. Their flat unloading curve ensures continuous, biologically favorable force delivery—minimizing patient discomfort.

Superior Vibration Damping

Compared to traditional wires, NiTi alloys are significantly more effective in dampening chewing-related vibrations and occlusal forces.Superelastic NiTi archwires reduce vibration amplitude by 50%, providing critical protection for periodontal tissues and reducing the risk of root resorption.

3. Classification of NiTi Orthodontic Wires

(Adapted from Evans & Durning)

1940s: Early Metal Wires

- Materials: Gold alloys, CoCr alloys, stainless steel.

- Limited flexibility, high stiffness.

1960s: Martensite-Stabilized NiTi

- Deformed in martensitic state.

- Lacks SME and SE.

- Features low stiffness and light forces.

1980s: Austenite-Active NiTi (Chinese/Japanese Type)

- The material stays in the austenite phase during typical environmental and oral temperature exposure.

- Superelasticity triggered by mechanical stress (no SME).

- High resiliency and low stiffness—ideal for early alignment.

- Limitations: Cannot be heat-treated or bent easily; may cause unpredictable arch expansion.

1990s: Martensite-Active (Thermal-Activated) NiTi

- Transition Temperature Range (TTR) near or just below oral temperature (~32°C).

- Can be shaped when cool (martensitic) and activated by body heat to exert force.

- Combines SME and SE properties.

- Brands: Smart (Beijing Smart Technology), Nitinol HA (3M).

- Force can be modulated by temperature changes (e.g., hot or cold water).

Graded Thermodynamic NiTi

- TTR higher than oral temperature (~40°C).

- Remains soft intraorally; transforms to austenite only when heated (e.g., hot water).

- Produces ultra-light forces—ideal for initial alignment in adults or periodontal patients.

- Brands: Omcro Cu-NiTi, Tomy L-H (Low Hysteresis).

4. Clinical Applications of NiTi in Orthodontics

Initial Alignment and Leveling

NiTi wires are the go-to choice for early-stage orthodontic treatment due to their excellent force characteristics and shape recovery.

Common Protocols:

- MBT Technique: 0.016″ Heat-Activated NiTi (HANT)

- Damon System: Omcro Cu-NiTi (TTR ~40°C)

- O-PAK Technique: 0.016″ Superelastic NiTi

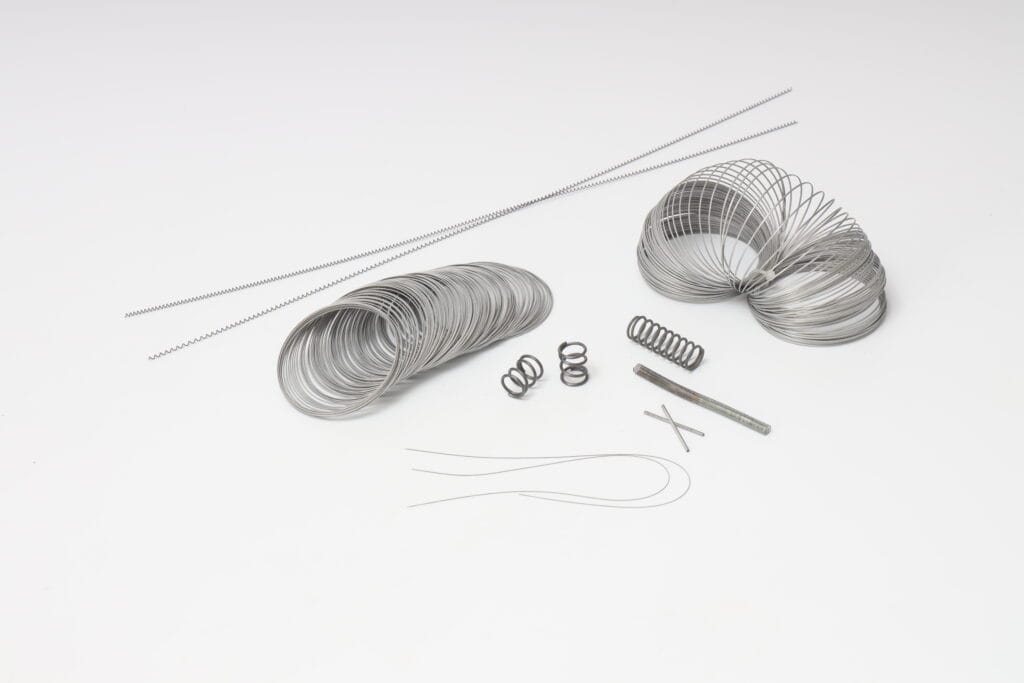

NiTi Coil Springs

Used for space closure or opening, these springs utilize NiTi’s superelasticity to deliver light, consistent forces (~50g/mm). Compared to stainless steel springs, they generate 3.5–4x less force at the same deflection, significantly reducing pain and treatment time.

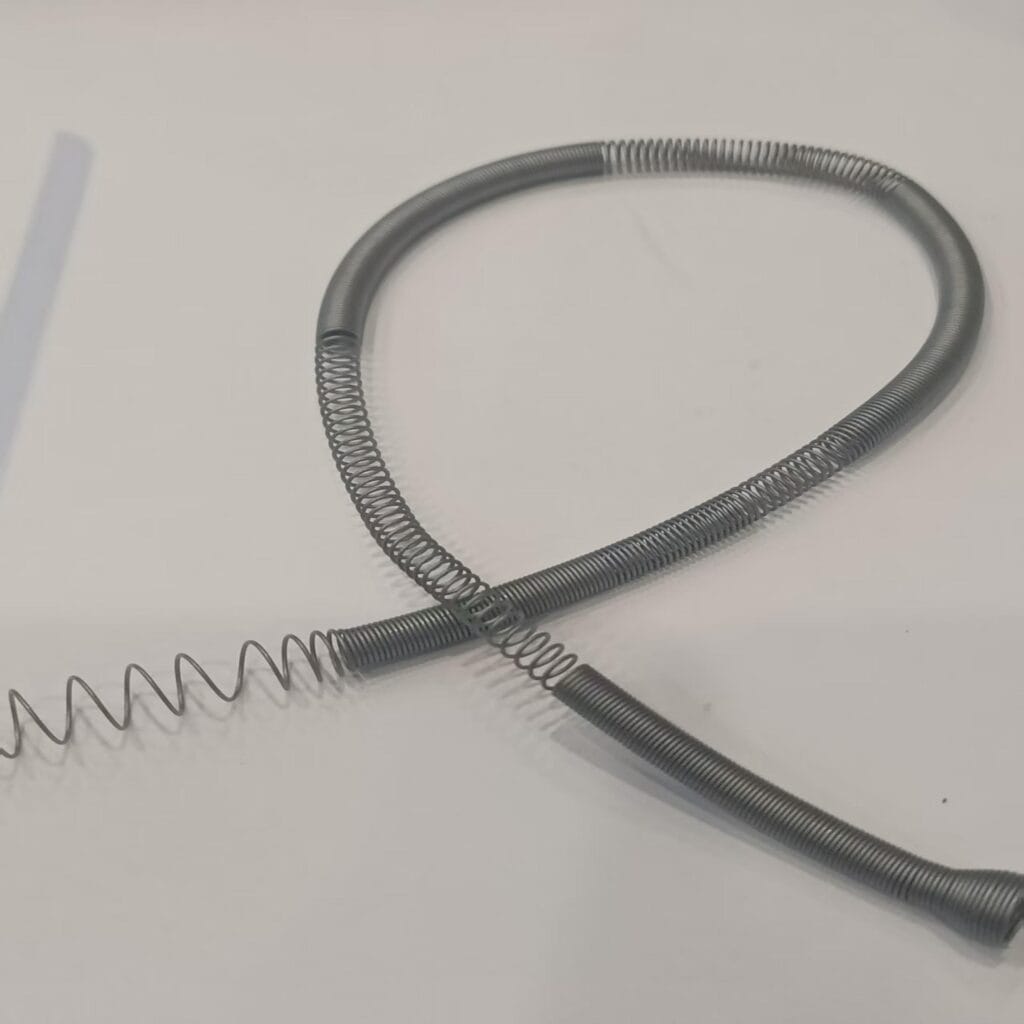

L-H Archwire (Tomy)

This specialized NiTi wire features:

- Low Hysteresis: Minimal force loss between activation and deactivation.

- High Titanium Content: Improved vibration damping.

- Formability: Allows chairside bending and heat-setting for personalized treatment adjustments.

L-H wires are effective for:

- Covers all treatment phases, including alignment, leveling, space closure, and final detailing.

- Managing complex cases: expansion, open bites, crossbites, and asymmetries.

- Clinical efficiency: Offers a simplified alternative to complex MEAW (Multiloop Edgewise Archwire) techniques when shaped into an accentuated curve with posterior tip bends.

Conclusion

Nickel-Titanium alloys represent a leading class of functional materials, uniquely combining mechanical versatility, biocompatibility, and smart responsiveness to stress and temperature changes.Whether in orthodontics, medical devices, or engineering applications, NiTi continues to revolutionize performance and design possibilities.