Jiangyin Haolu Ni Ti New Materials Co,.Ltd.

Haolu Technologyis located in Jiangyin City, Jiangsu Province, China.

Forover 10 years, we have been forging ahead on the path of nickel titanium,providing one-stop solutions from processing nickel titanium medical mate-rials to assembling nickel titanium precision components.

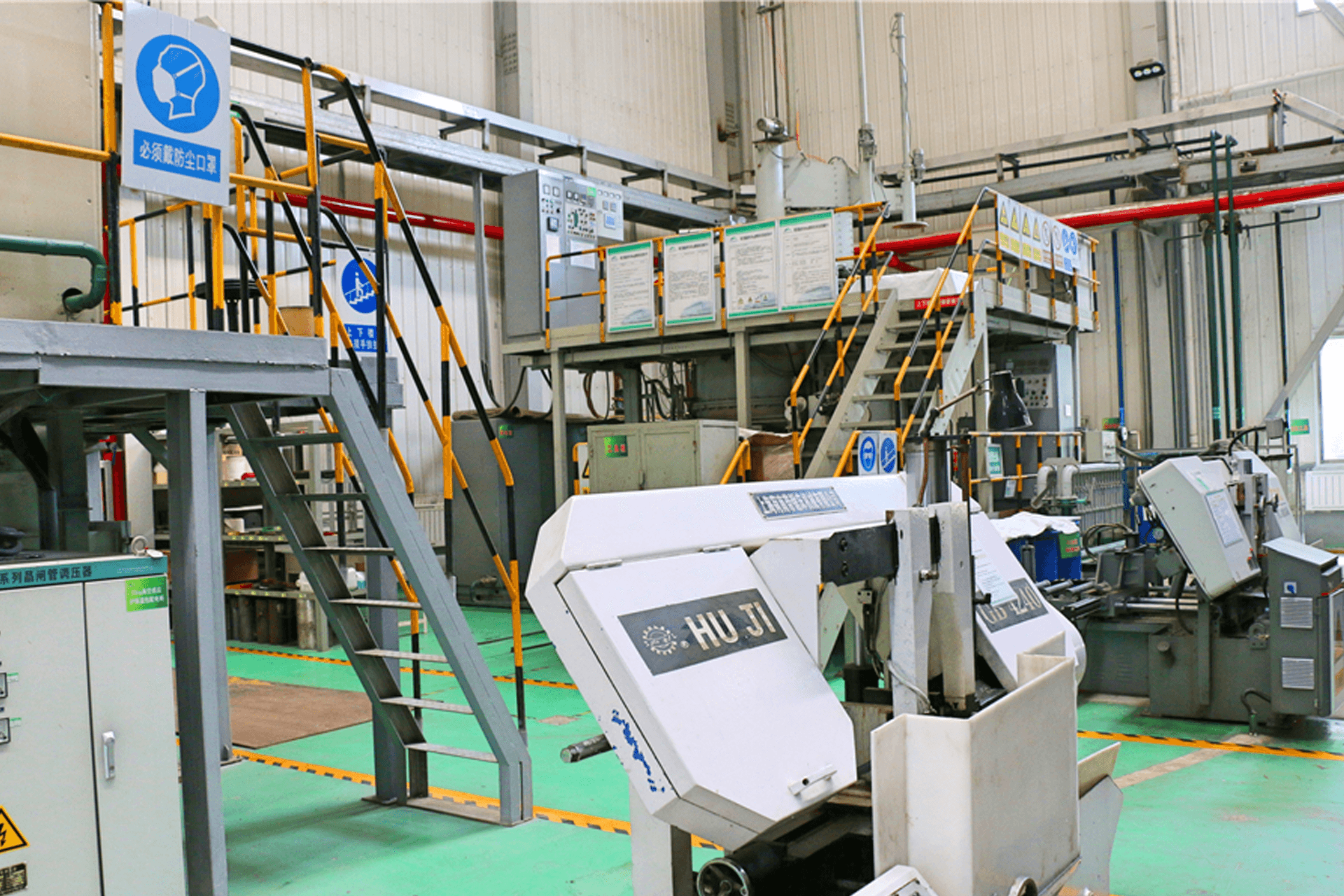

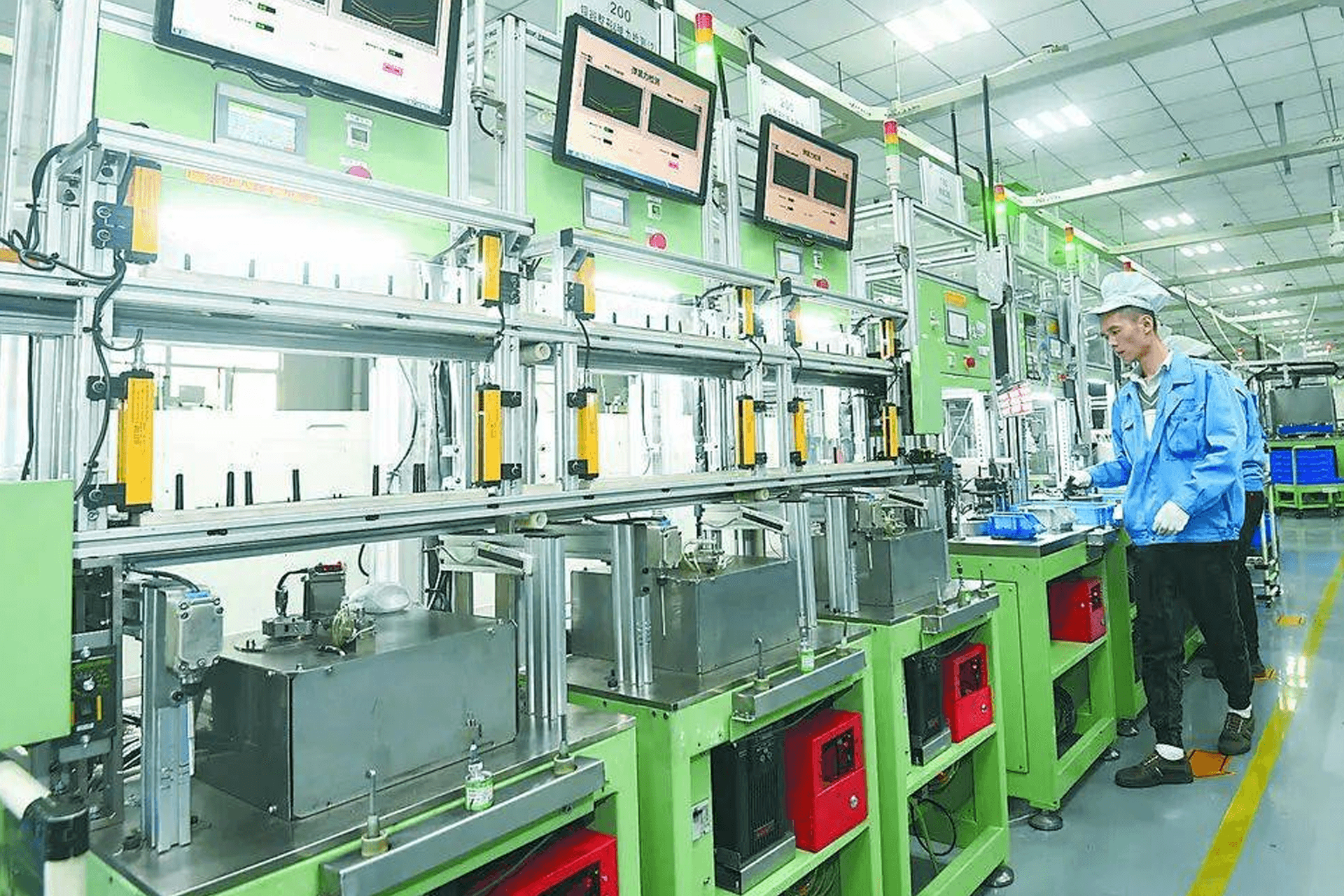

We independentlydevelop mechanical equipment for the production and processing ofnickeltitanium materials, and have also introduced advanced instruments andequipment such as laser cutting machines and precision testing.

Producehigh-quality materials for brackets, guide wires, sutures, magnesium alloydegradable pipes, absorbable sutures, medical nickel state memory alloypipes, various nickel titanium springs and shaping, nickel titanium microfila-ments and other medical nickel titanium memory alloy materials and prod-ucts.Carved between tiny particles, pickled, polished, and passivated, with acomplete surface treatment process.

Strive to “customer-oriented, quality for survival, to win with excellence, to fine map new” all-round management, to provide high-quality services for the society.

The company strictly operates in accordance with the international quality certification system, based on the direction of enterprise management, constantly improve the service level, standardize the internal operation, and achieve the integration with the international management level.

We are thoroughly impressed with the exceptional quality of your nickel-titanium alloy wire. Its consistent superelastic properties and precise dimensional tolerances have significantly improved the performance of our medical device prototypes. After rigorous testing, the wire demonstrated remarkable fatigue resistance and shape memory retention, exceeding our industry standards. Your team's commitment to material excellence and technical support has made you an indispensable partner for our R&D projects. We look forward to expanding our collaboration!

The nickel-titanium alloy wire we received has been a game-changer for our manufacturing process. Not only did it arrive with flawless surface finish and zero defects, but its mechanical properties also remained stable through multiple production cycles. Our quality control team confirmed near-perfect compliance with ASTM F2063 specifications. The combination of your material's reliability and your responsive customer service has streamlined our operations and reduced downtime. Highly recommended for mission-critical applications!