Medical-Grade Nitinol Staple – Orthopedic Implant Solution

Medical-Grade Nitinol Staple for Stable Bone Fixation

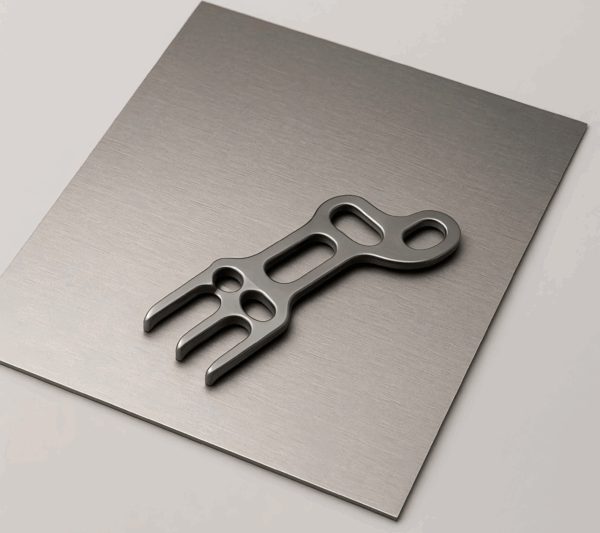

The medical-grade nitinol staple is a superelastic orthopedic implant designed to provide stable and continuous bone fixation during surgical procedures. Manufactured from high-purity nickel-titanium alloy, this medical-grade nitinol staple complies with ASTM F2063 and is produced under a certified ISO 13485 quality management system, ensuring safety, consistency, and long-term clinical reliability.

Thanks to its excellent biocompatibility and corrosion resistance, the medical-grade nitinol staple is suitable for long-term implantation inside the human body.

Material & Standards of Medical-Grade Nitinol Staple

Our orthopedic staples are manufactured using certified medical-grade Nitinol (Nickel-Titanium alloy) specifically developed for surgical implants.

Material: Medical-Grade Nitinol

Standard: ASTM F2063

Quality System: ISO 13485

Condition: Superelastic

MRI Compatibility: Yes

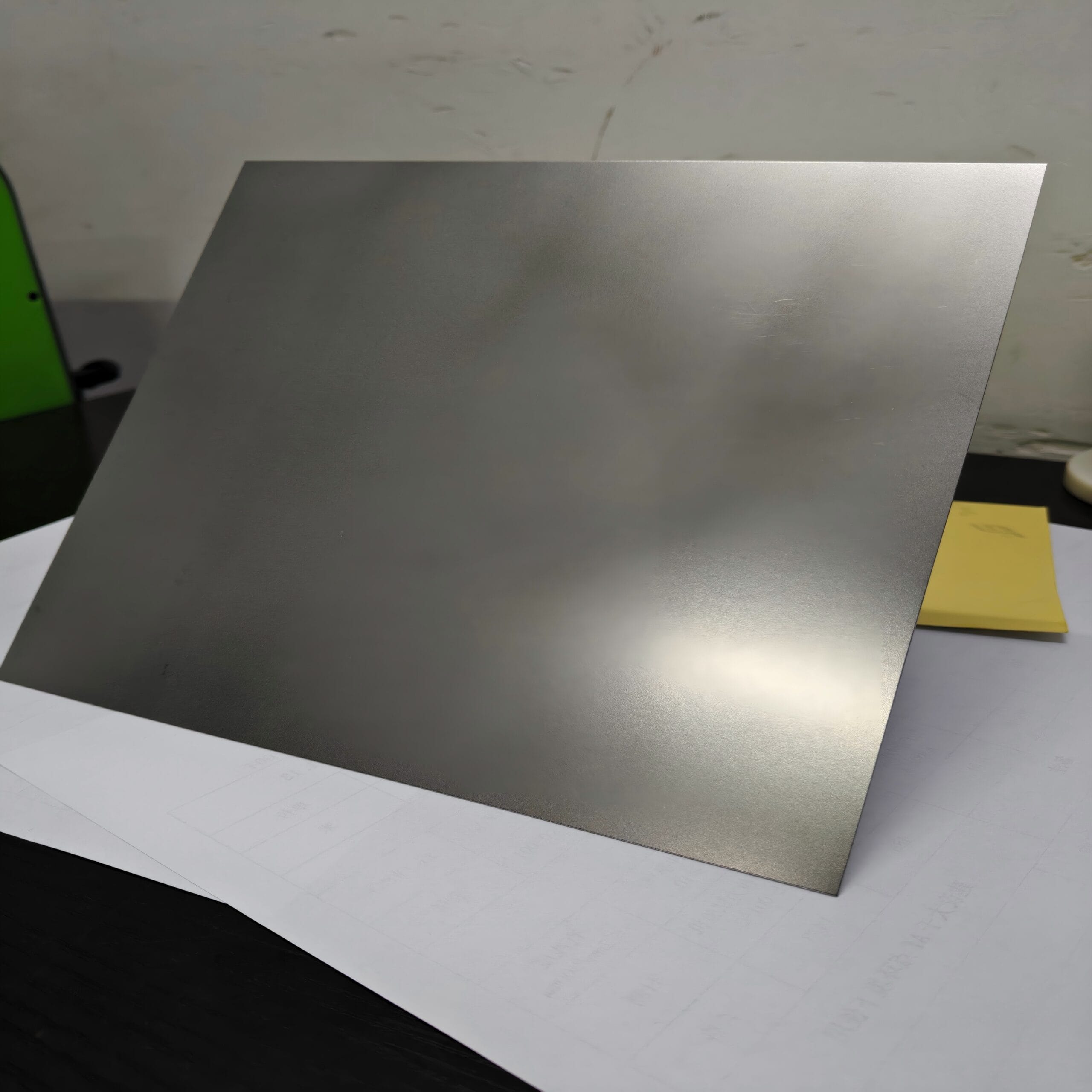

The polished surface finish minimizes tissue irritation and supports safe interaction with bone and surrounding soft tissue.

Superelastic Performance and Active Compression

A key advantage of the medical nitinol staple is its unique superelastic fixation mechanism. During implantation, the staple legs are temporarily compressed for easy insertion into pre-drilled bone holes. Once released, the legs automatically expand and apply continuous, controlled compression across the fracture or osteotomy site.

This active compression adapts to micro-movements during healing, improving fixation stability and reducing the risk of loosening compared to conventional rigid metal staples.

Applications of Medical-Grade Nitinol Staples

Medical-grade nitinol staples are widely used in orthopedic procedures such as:

Osteotomies

Bone fracture fixation

Joint fusion procedures

Foot, hand, and spinal surgeries

Their compact design and self-compressive force make them ideal for minimally invasive and anatomically constrained applications.

Precision Manufacturing & Quality Control

We specialize in the production of medical nitinol staples for orthopedic and surgical applications.

A dedicated shape-setting heat treatment defines the final superelastic form and compression force. Mechanical polishing, edge rounding, and advanced cleaning and passivation processes ensure excellent corrosion resistance and biocompatibility.

Each production batch undergoes strict inspection, including dimensional verification, surface quality assessment, and mechanical performance testing. Full traceability documentation is available to support regulatory submissions.

Ordering & Custom Development

We supply standard models and customized nitinol staple solutions to OEM and medical device companies worldwide. Our engineering team supports product design, size optimization, and compliance with international medical standards.

Medical Nitinol Wire →Medical Grade Nitinol Wire

Nitinol Implant Manufacturing → Nitinol Cable Medical Use – Superelastic Wire & Alloy Guide – Ni Ti New Materials

- Medical Nitinol Tubing→Custom Helical Nitinol Tubes | Nitinol Tube Drawing Manufacturer – Ni Ti New Materials

Reviews

There are no reviews yet.