Nitinol Shape Setting Services for Semi-Finished Medical Catheter Tubes

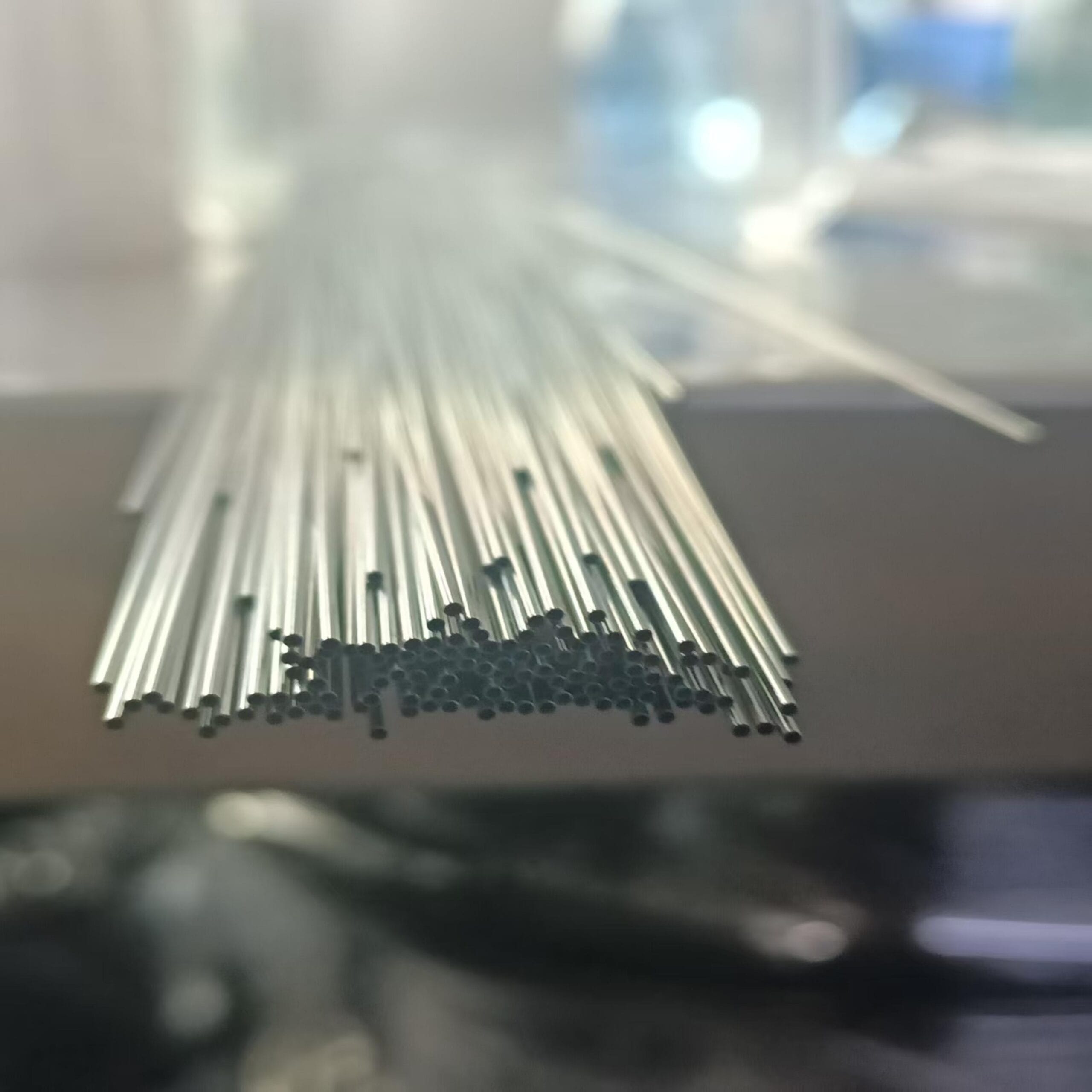

Premium Semi-Finished Nitinol Tubes with Expert Shape Setting

Our Nitinol Shape Setting Services begin with semi-finished tubes made from premium Nickel-Titanium alloy. Known for its superior superelasticity and shape memory properties, Nitinol enables catheters to bend effortlessly and return to their original shape. These tubes are designed to perform consistently at body temperature, ensuring reliable medical device function. We source high-purity materials to guarantee medical-grade quality in every batch.

Surface Finishes Enhancing Nitinol Tubes for Catheter Use

We offer a range of smooth surface finishes tailored for medical applications, including bright annealed, chemically etched, and electropolished options. Electropolishing, in particular, enhances our Nitinol Shape Setting Services by removing micro-imperfections, reducing friction, and preventing bacterial buildup. This ensures biocompatibility and safer catheter navigation.

Custom Diameter and Thickness Options for Medical Devices

Our semi-finished Nitinol tubes come in diameters from 0.1 mm to 10 mm and wall thicknesses from 0.025 mm to 1.5 mm. We adapt quickly to custom size requests, delivering precision tubing to meet the exact needs of catheter shafts, guidewires, stent delivery systems, and more. Our shape setting process preserves these dimensions for reliable device performance.

Key Applications of Nitinol Tubes with Shape Setting

Catheter Shafts: Flexible, kink-resistant tubing shaped via our expert services.

Guidewires: Accurately shaped, maneuverable wires designed for navigating vascular pathways.

Stent Delivery Systems: Shape-set sleeves for accurate deployment.

Neurological Tools: Specialized, custom-formed elements for neurological and spinal interventions.

Endoscopic Instruments: Slim, agile devices made possible by shape setting.

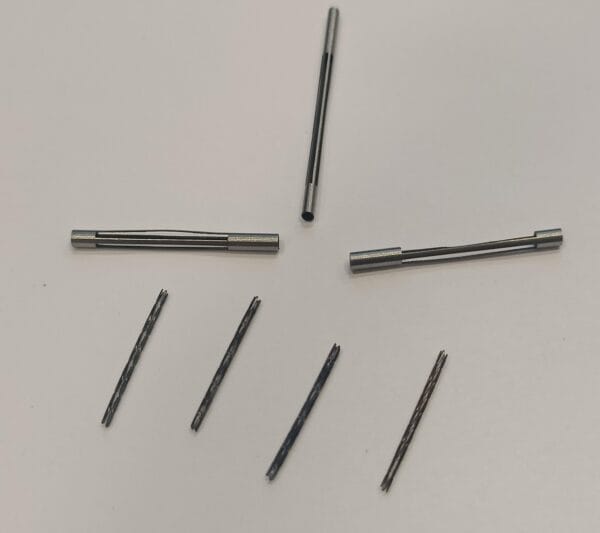

Advantages of Our Nitinol Shape Setting Services

Our specialty in Nitinol Shape Setting Services allows us to program complex curves and 3D geometries into tubes using controlled heat treatment and precision jigs. This process streamlines production, minimizing assembly efforts and lowering costs.All tubes comply with ISO 13485 and FDA medical-grade standards. We offer rapid prototype delivery within 72 hours and ensure quality with laser measurements, tensile testing, and traceability from melt to final product. Our engineering team provides technical support to optimize catheter design and performance.

Request Custom Nitinol Shape Setting Today

Leverage our advanced Nitinol Shape Setting to receive perfectly formed tubing for your medical devices. Contact us now for samples and elevate your catheter reliability and patient safety.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.