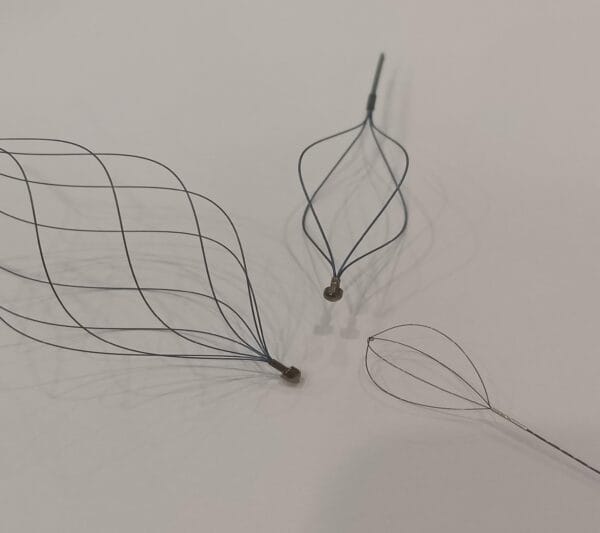

Material Composition

This wire passer is using nitinol shape memory alloy, precisely composed of Ni Ti. Celebrated in the medical field for its responsive behavior, the alloy quickly reverts to its pre-set shape when exposed to specific temperature shifts—even after undergoing significant deformation. This “smart material” delivers performance that feels almost instinctive, making it invaluable in demanding surgical environments.With 30 times greater elastic recovery than standard metals, it’s rigorously tested to ISO 10993 biocompatibility standards and has already proven safe in 200,000+ clinical cases, including cardiac stents and bone fixation systems.

Lab results show it withstands 1 million bend cycles without failure—perfect for repetitive motions in minimally invasive surgery. Unlike ordinary wires, our nitinol alloy combines surgical-grade precision with industrial toughness, making it the go-to choice for surgeons who demand both flexibility and reliability.

Smooth, Polished Surface Finish

Each wire passer undergoes a thorough polishing process. This removes surface imperfections and reduces friction during procedures. As a result, the polished surface resists corrosion and contamination. Additionally, the medical-grade finish enhances compatibility with sensitive tissues and lowers infection risk.

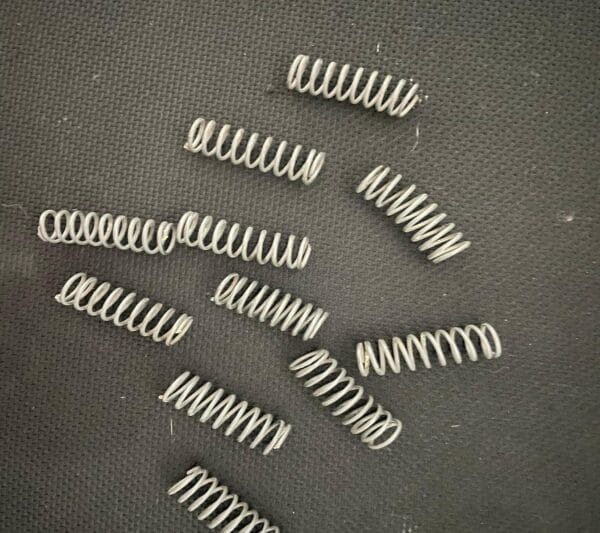

Versatile Diameter Range

This wire passer supports diameters ranging from 0.1 mm to 2.0 mm. Thanks to this versatility, it works well in both microsurgery and orthopedic settings. Thin wires enable precise movements in tight spaces, while thicker wires provide needed strength for load-bearing tasks.

Key Applications

The device excels in minimally invasive surgery, cardiovascular interventions, and orthopedic repairs. Surgeons use it for suturing, stent placement, and bone alignment. Besides medical uses, engineers integrate it into robotics and aerospace systems for reliable actuation. It also finds use in automotive and consumer electronics for sensors and connectors.

Why Choose Our Nitinol Alloy Shape Memory Wire Passer?

Exceptional Shape Memory & Superelasticity

Due to the nitinol alloy shape memory effect, the wire passer can endure repeated bending without permanent damage. It naturally resumes its predefined structure after deformation.This resilience reduces device failure and extends service life.

Precision Manufacturing

Strict diameter control ensures consistent performance across wire sizes. Furthermore, the smooth surface prevents snagging during procedures, allowing smooth navigation.

Biocompatibility & Safety

Certified for medical use, the wire passer resists body fluids, heat, and sterilization processes. Plus, it is non-magnetic, making it safe for MRI environments.

Custom Solutions & Fast Delivery

You can customize diameter, length, and curvature. Fast prototyping combined with large-scale manufacturing ensures swift delivery.

Trusted Quality & Cost Efficiency

Each batch undergoes rigorous testing for fatigue resistance, tensile strength, and temperature stability. This leads to decreased maintenance expenses and improved system uptime.

Final Benefits

The nitinol alloy shape memory wire passer combines advanced material science with practical design. It meets the challenges of healthcare, manufacturing, and technology sectors alike. Whether for wound closure or smart device assembly, this tool delivers reliable, predictable results every time. Choose nitinol for innovation that adapts and performs perfectly.

▸ Expert Guidance: 24/7 support via nitinolalloy.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.