Nitinol Tube for Medical Devices – Cleaned with NDC Precision

Experience the power of nitinol tube technology engineered for high-performance medical devices. Our advanced Nitinol Medical HypoTube combines the unique properties of nickel titanium alloy with precision manufacturing and NDC cleaning. Designed for reliability, flexibility, and biocompatibility, this micro-tube solution supports breakthrough innovations in minimally invasive healthcare.

Medical-Grade Nitinol Tube: Strong, Flexible, and Biocompatible

Our nitinol tubes are crafted from high-purity, medical-grade alloy known for its superelasticity and shape memory. This enables devices to bend, compress, or stretch—then recover perfectly to their original form. It’s ideal for applications navigating complex anatomy. With excellent fatigue resistance, corrosion protection, and proven biocompatibility, our nitinol tube ensures safe and long-term performance inside the body.

Enhanced Tube Cleanliness with Smooth Finish and NDC

We deliver ultra-smooth internal and external surfaces, critical for minimizing friction and tissue trauma. Our surface finishing prevents bacterial adhesion and supports consistent device function. Every nitinol tube is treated with our proprietary Non-Destructive Cleaning (NDC) process, removing contaminants without damaging the material. This ensures optimal cleanliness, safety, and performance for medical environments.

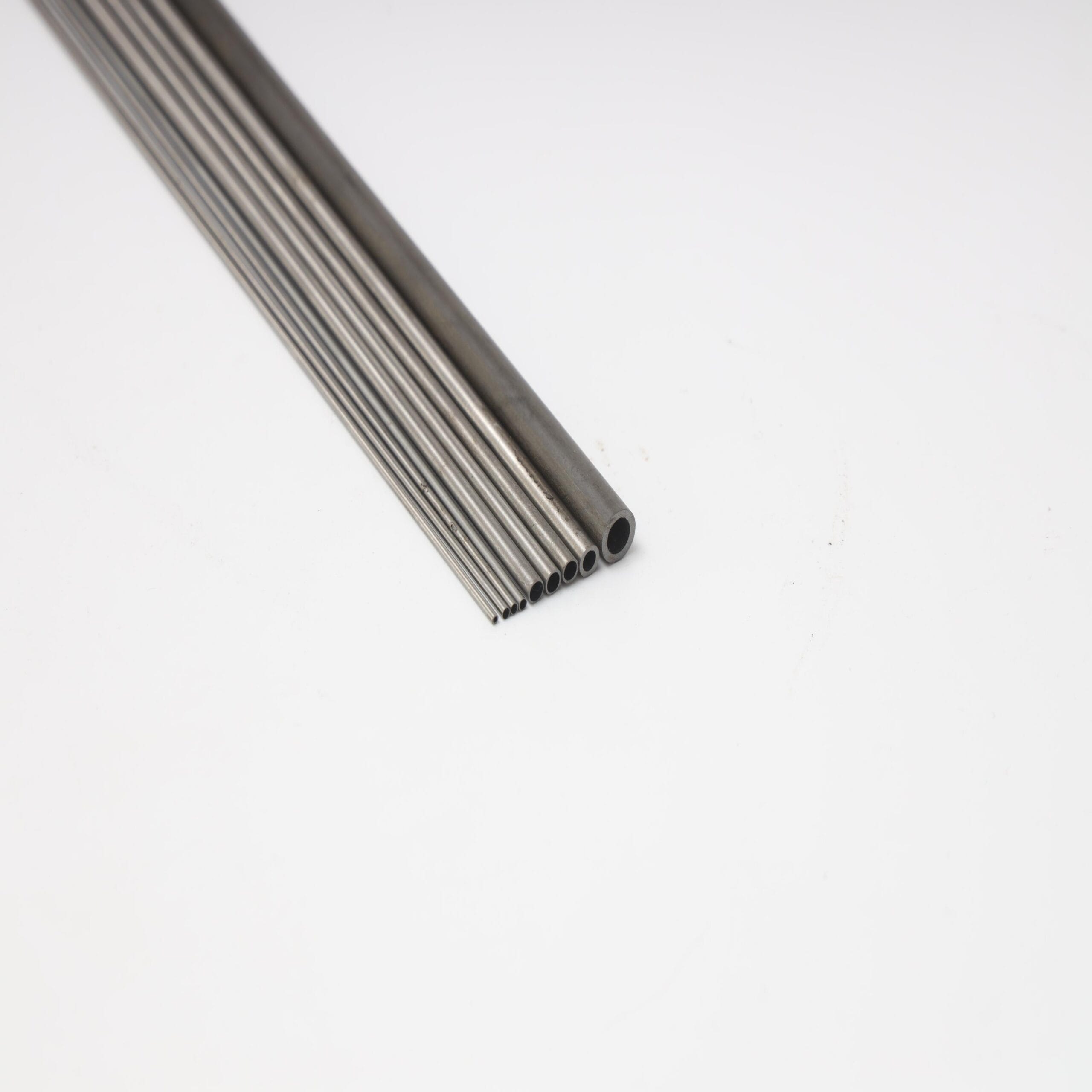

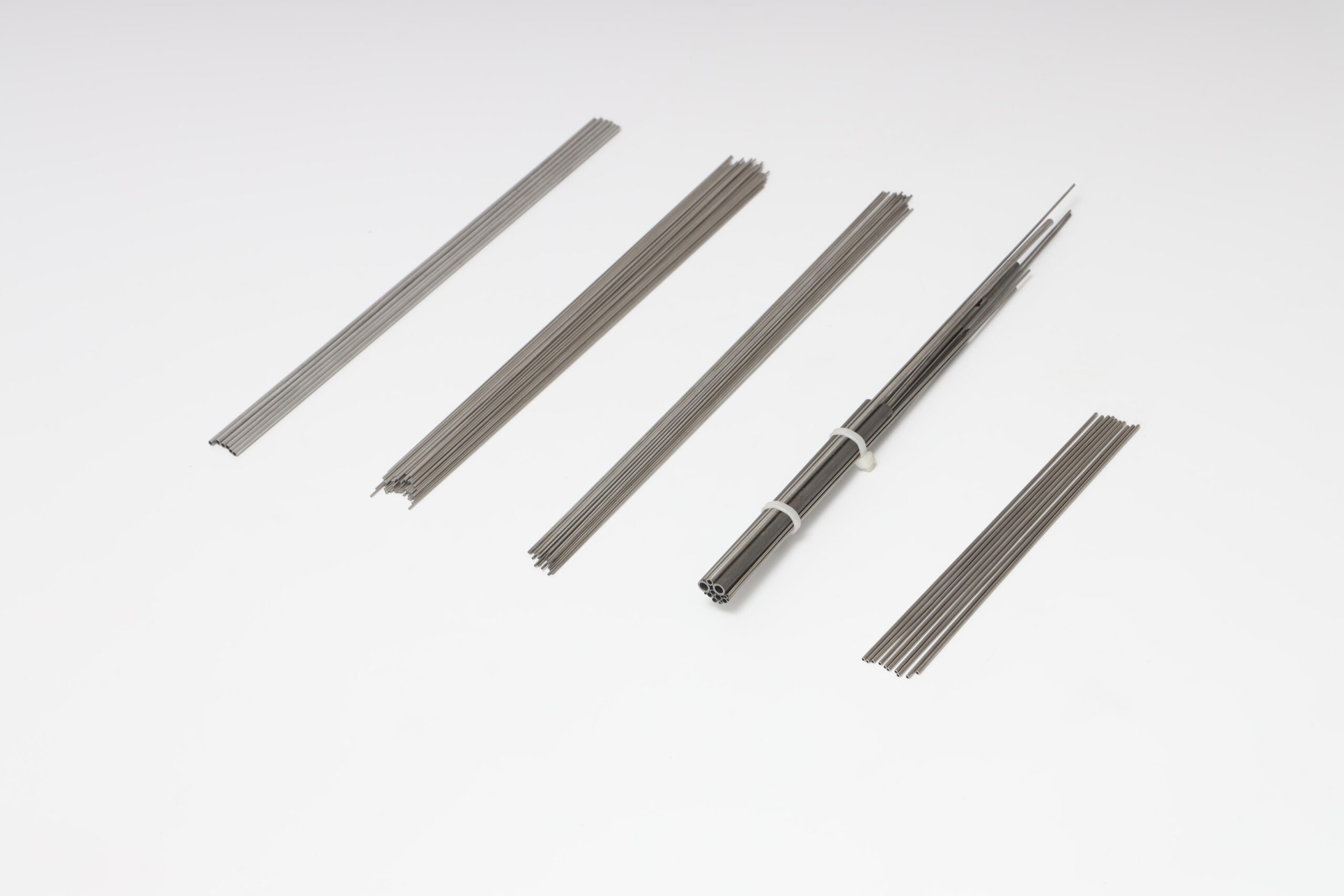

Precision Dimensions for Micro-Scale Applications

We manufacture nitinol tubes with diameters as small as 0.001 inches (0.025 mm) and up to 0.100 inches (2.54 mm), with tight tolerances and excellent concentricity. Choose the right inner diameter and wall thickness to match your design needs—whether for flexibility, torque control, or strength. Dimensional accuracy allows seamless integration into intricate device assemblies.

Trusted in Critical Medical Applications

Nitinol tube solutions are essential across a wide range of life-saving devices:

Minimally Invasive Surgery: Guidewires, catheter shafts, etc

Neurovascular Devices: Thrombectomy tools, steerable micro-catheters

Cardiovascular Applications: Stent delivery, electrophysiology catheters

Peripheral Vascular Procedures: Atherectomy and PTA balloon catheters

Endoscopic Systems: Steerable scopes and biopsy instruments

Orthopedic & Spinal Tools: Fixation and delivery components

Diagnostic Probes: Pressure sensing and imaging devices

Why Choose Our Nitinol Tubes with NDC Cleaning?

Precision Nitinol Expertise: Guaranteed superelastic and shape memory behavior

Medical-Grade Manufacturing: Certified materials and cleanroom environments

Surface Perfection: Tubes with exceptional smoothness for minimal friction and superior cleanliness

Validated NDC Protocols: Thorough cleaning ensures biocompatibility

Meticulous Quality Control: Full inspection, traceability, and documentation

Custom Dimensions Available: We match your exact specs and prototype needs

Reliable Global Delivery: Strong inventory management ensures on-time supply

Innovation Partnership: Collaborating with you to solve complex challenges

Invest in High-Precision Nitinol Tubes with NDC Cleaning

Advance your next-generation medical devices with our reliable nitinol tube solutions. Engineered for performance and cleaned to perfection with NDC, our tubes support safer, more effective healthcare technologies. Contact us today to discuss your design requirements. Let’s build something extraordinary—together.

Reviews

There are no reviews yet.