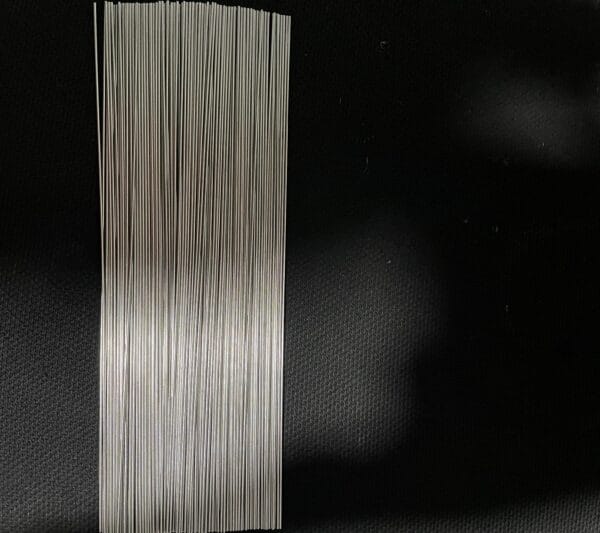

Precision Laser-Cut NDC Nitinol Tubing for Advanced Applications

Opt for Nitinol tubing for high-quality, laser-cut tubes engineered to perform exceptionally in challenging conditions.Our tubing leverages the exceptional properties of Nitinol — including shape memory and superelasticity — ensuring reliable, high-performance operation across diverse industries.

Premium Material Selection for Optimal Performance

Our ndc Nitinol tubing is crafted exclusively from top-grade Nitinol alloy that complies with strict standards such as ASTM F2063. This ensures excellent biocompatibility, making it perfectly suited for essential medical device applications. Thanks to its unique shape memory, the tubing returns to its original form after deformation, coupled with remarkable flexibility similar to a spring. These features make it perfect for applications requiring precise positioning and repeated mechanical movement.

Superior Surface Finishes Tailored to Your Needs

We provide a variety of surface finishes to optimize your tubing’s performance. Select a polished, ultra-smooth finish to minimize friction—ideal for internal moving components in medical implants. Alternatively, choose an etched surface for enhanced adhesion when applying coatings. Our tight control of surface roughness (low Ra values) ensures suitability for even the most demanding uses. Each tube undergoes meticulous cleaning to remove laser-cutting residues, delivering a ready-to-use, contaminant-free product.

Wide Diameter Range and Custom Sizing

Whether your project requires micron-scale tubing or larger millimeter diameters, ndc Nitinol tubing offers unmatched diameter flexibility. We provide common standard sizes and gladly accommodate custom diameter specifications with laser-cut precision, ensuring an exact fit for your specialized application.

Applications Where NDC Nitinol Tubing Excels

Medical Devices: Manufacture life-saving implants such as vascular stents, heart valve frames, orthopedic staples, guidewires, catheters, and surgical instruments. Benefit from biocompatibility and MRI safety.

Minimally Invasive Surgery (MIS): Enable intricate, flexible instruments for laparoscopy and endoscopy, navigating complex anatomy with ease.

Filters & Occluders: Build reliable IVC filters and septal occluders utilizing Nitinol’s superelastic properties for secure deployment.

Industrial Actuators & Sensors: Develop responsive actuators, thermal sensors, and release mechanisms powered by shape transformation.

Fluid Flow Systems: Create smart valves, connectors, and couplings that react automatically to temperature changes.

Aerospace & Defense: Fulfill stringent requirements with lightweight, reliable tubing ideal for wing actuators, deployable structures, and panels.

Consumer Electronics: Integrate micro-actuators for cameras, microphones, and adjustable device components.

Research & Prototyping: Obtain precisely laser-cut samples to accelerate product development and testing.

Why Choose NDC Laser-Cut Nitinol Tubing?

Exceptional Accuracy: Utilizing state-of-the-art laser technology, we consistently produce detailed cuts with precise tolerances and sharp, clean edges.

Expert Material Knowledge: Our deep understanding of Nitinol processing and heat treatment ensures peak superelasticity and shape memory.

Rigorous Quality Control: Comprehensive inspections verify dimensions, surface finish, and material properties, backed by certifications such as Material Certs and C of C.

Versatile Capabilities: From standard sizes to complex custom designs, we support all project scopes efficiently.

Clean & Safe Manufacturing: Our contaminant-free process is crucial for sensitive medical and industrial applications.

Proven Reliability: Depend on our tubing in critical implants, actuators, and sensor systems.

Responsive Collaboration: We prioritize understanding your needs, providing expert technical support and fast, effective solutions.

Fast Turnaround: We respect your timelines with streamlined production and delivery schedules.

Contact us today to discuss your application and experience the ndc nitinol tubing difference in quality, precision, and reliability.

Reviews

There are no reviews yet.