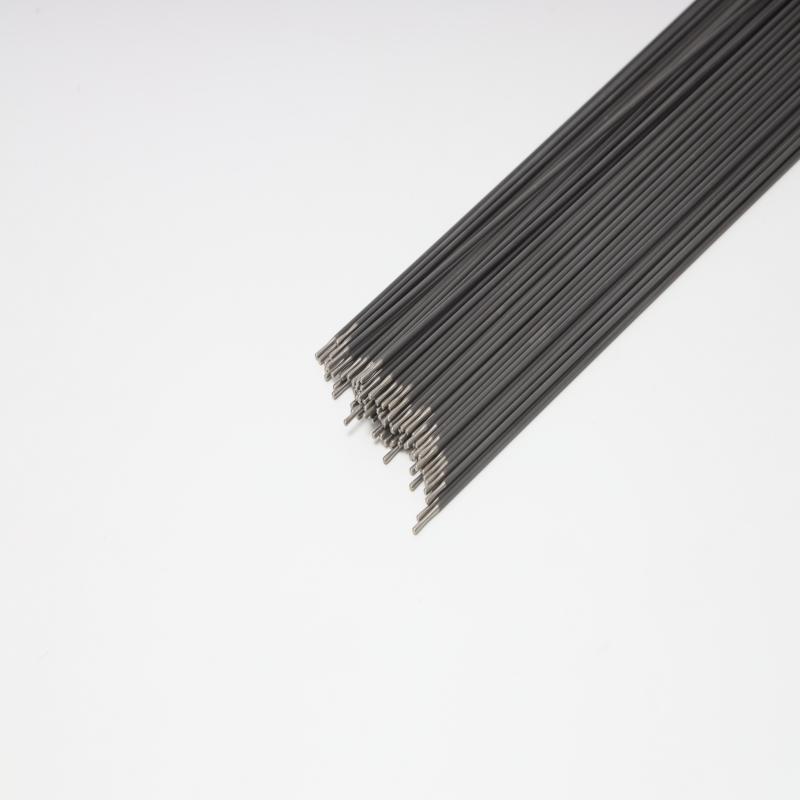

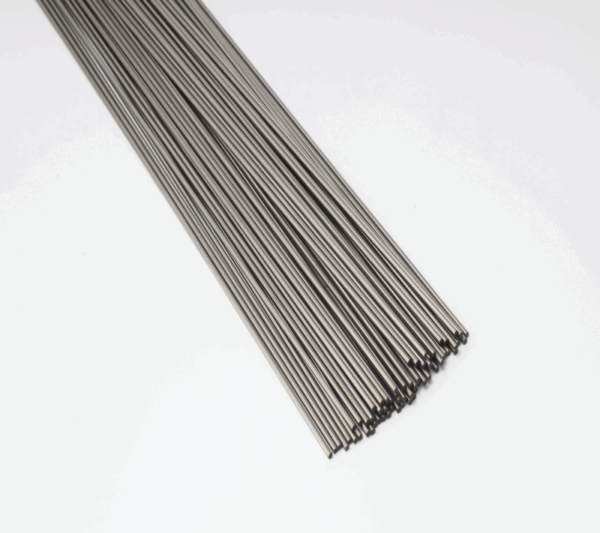

Precision Nickel Titanium Rods with Laser Cutting Technology

Premium Laser Cutting Nitinol Rod Material

Our rods start with medical-grade Nitinol, a nickel-titanium alloy renowned for superelastic flexibility and shape memory capabilities. This advanced material bends under stress yet snaps back to its original form—perfect for components requiring repeated motion or temperature-triggered actions.

Versatile Surface Finishes for Laser Cutting Nitinol Rods

We offer a range of surface finishes tailored to maximize the benefits of laser cutting nitinol rods. Choose from polished finishes that reduce friction for medical instruments, matte finishes to improve grip on industrial components, sandblasted surfaces for scratch resistance, or etched finishes perfect for laser engraving. Each finish undergoes rigorous quality control to guarantee smoothness and durability suited to your application needs.

Comprehensive Diameter Range

Our rods range from 0.1 mm to 25 mm in diameter, covering everything from delicate medical devices like stents and guidewires to robust aerospace actuators and automotive tools. Custom diameter and length options are available to meet specific project requirements, ensuring your components are precisely what you need.

Applications of Nitinol Rods

Thanks to their remarkable properties and precision manufacturing, our laser cutting nitinol rods are used in:

Medical devices: surgical tools, stents, orthodontic wires

Aerospace parts: actuators, satellite components, vibration dampers

Automotive systems: fuel injectors, clutch systems, exhaust valves

Robotics: flexible joints, grippers, sensors

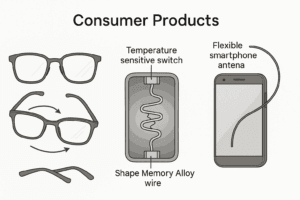

Consumer products: eyeglass frames, phone antennas, sports equipment

Why Choose Our Nitinol Rods?

Using advanced fiber laser technology, we achieve cutting tolerances within ±0.01 mm, preserving the alloy’s shape memory and superelastic properties. Fast production times—prototypes within 3 days and bulk orders in 2 weeks—combined with rigorous quality tests and certifications like ISO 9001 and ASTM F2063, ensure dependable, top-tier rods every time. Plus, our eco-friendly manufacturing practices and global shipping make us the reliable partner for your nitinol needs.

ASTM F2063 Standard (https://www.astm.org/Standards/F2063.htm)

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.