Nitinol Core Wire Guide – EO Sterilized for Precision in Medical and Industrial Use

The nitinol core wire guide is engineered for precision and reliability, making it an ideal choice across both medical and industrial sectors. Its unique combination of flexibility, strength, and sterilized readiness ensures it performs exceptionally in complex environments—from the human body to demanding machinery.

Superior Material Composition

This wire guide is built from high-grade nickel-titanium alloy, commonly known as nitinol—a material celebrated for its unique combination of superelasticity and shape memory. It effortlessly bends under pressure and then returns to its original shape, even after repeated use. Thanks to these characteristics, nitinol performs exceptionally well in environments where flexibility, strength, and resilience under temperature changes are essential.

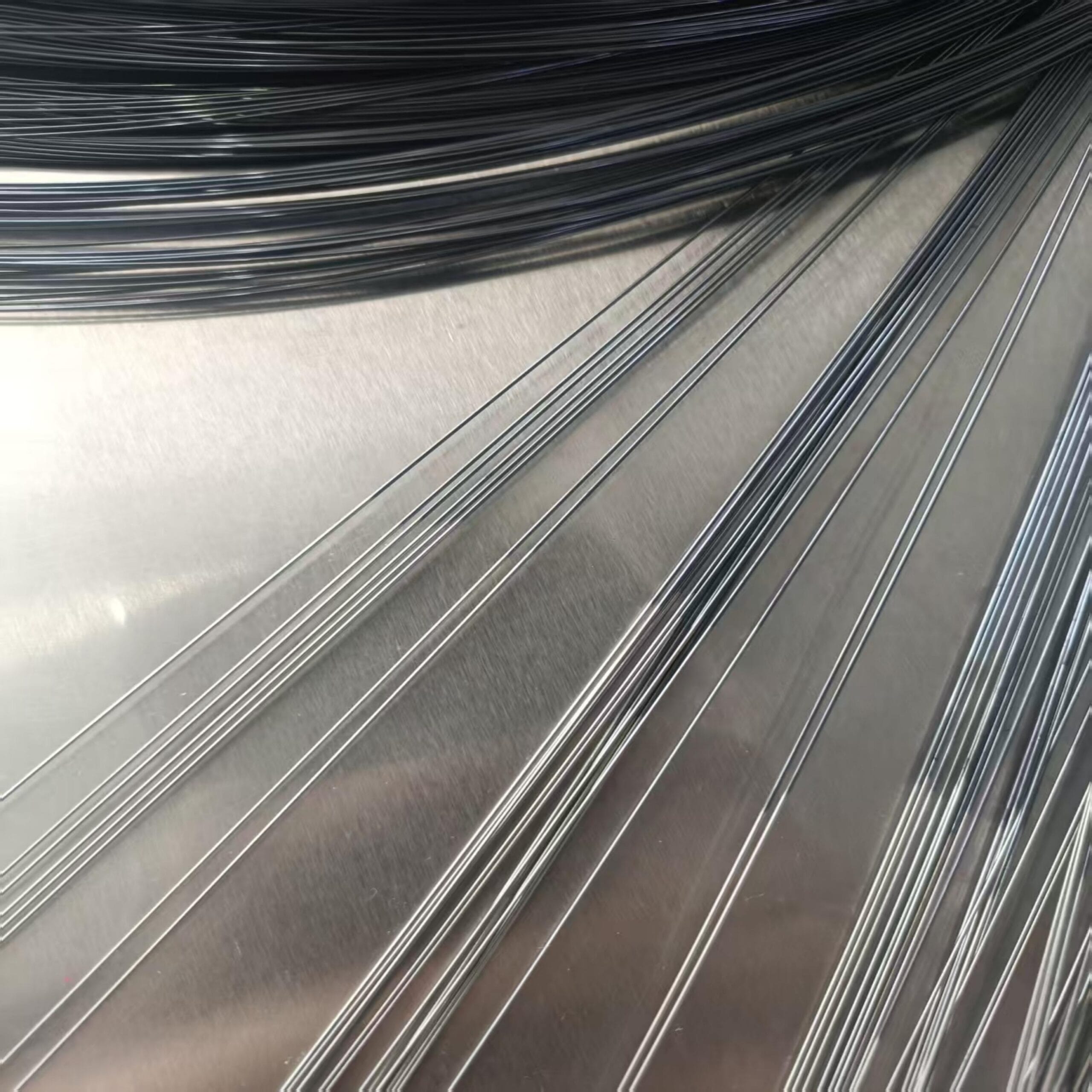

Smooth Surface with EO Sterilization

The surface undergoes precision grinding, which eliminates imperfections and enhances smoothness. This process not only reduces friction but also extends the wire’s lifespan. After grinding, the wire is EO (ethylene oxide) sterilized. Unlike harsh sterilization methods, EO effectively eliminates bacteria and viruses without compromising the wire’s structure. As a result, the product is ready to use in sterile environments such as operating rooms.

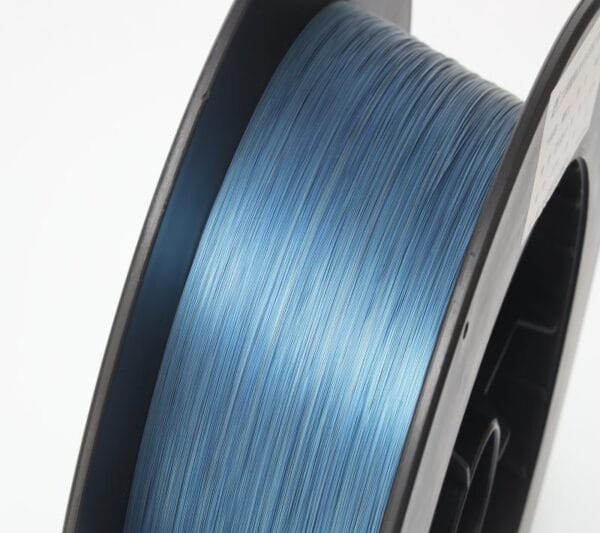

Customizable Diameter Range

This nitinol core wire guide is available in various diameters, from as thin as 0.10 mm for delicate procedures to 2.0 mm for more robust applications. Additionally, custom sizing options are available to meet specific project demands. Tight diameter tolerances ensure reliable integration with medical instruments and industrial devices.

Diverse Application Fields

In healthcare, the wire functions as a guidewire for cardiovascular, endoscopic, and orthopedic procedures. It smoothly navigates complex anatomical pathways, minimizing patient trauma. In industrial settings, it’s used in robotics, aerospace engineering, and precision equipment, where resistance to corrosion and mechanical fatigue is critical.

🔧 Why Choose Our Nitinol Core Wire Guide?

Reliable Performance

The wire’s nitinol structure ensures consistent performance during repeated bending, making it highly dependable.Enhanced Safety

EO sterilization guarantees safety for medical applications, reducing contamination risks in sensitive environments.Extended Durability

A precisely ground surface lowers friction and wear, increasing operational lifespan and efficiency.Versatile Sizing

A wide diameter range and customizable options allow engineers and surgeons to find the ideal fit for any use case.Proven Quality

Every wire undergoes testing for flexibility, strength, and sterility. Products comply with ISO and medical device standards, ensuring global acceptance.Reduced Operational Costs

Because of its longevity and reliability, the wire minimizes replacement frequency and cuts maintenance time.Responsive Support

Our expert technical team provides guidance for product selection and usage, helping you meet deadlines and avoid costly delays.

✅ Conclusion

This EO sterilized nitinol core wire guide combines material innovation with practical design. From operating rooms to assembly lines, its flexibility, surface precision, and sterilization make it a trusted component for professionals worldwide. When performance and safety matter most, choose a solution that delivers both.

Reviews

There are no reviews yet.