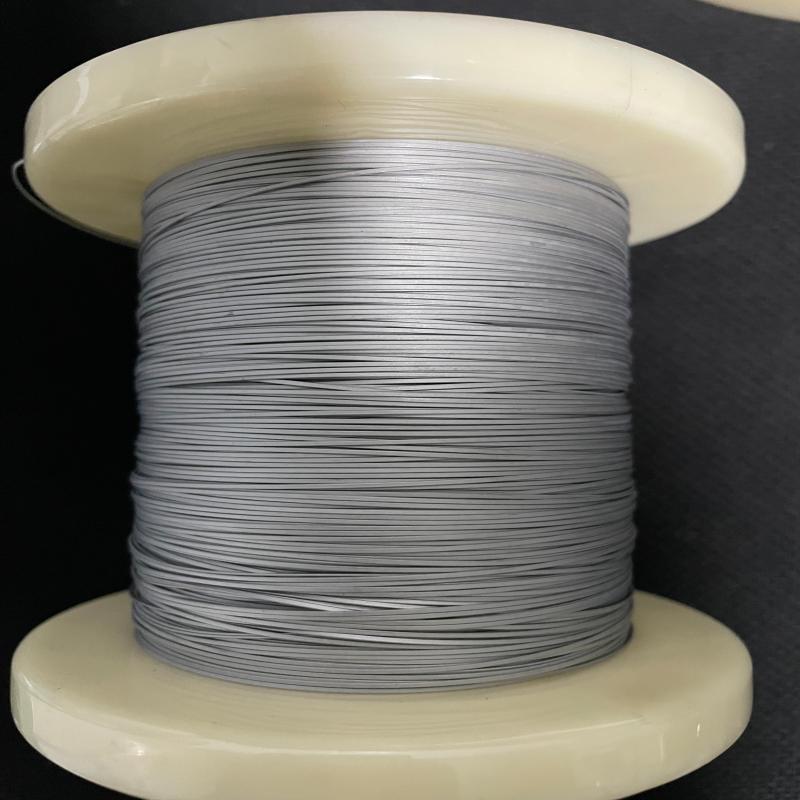

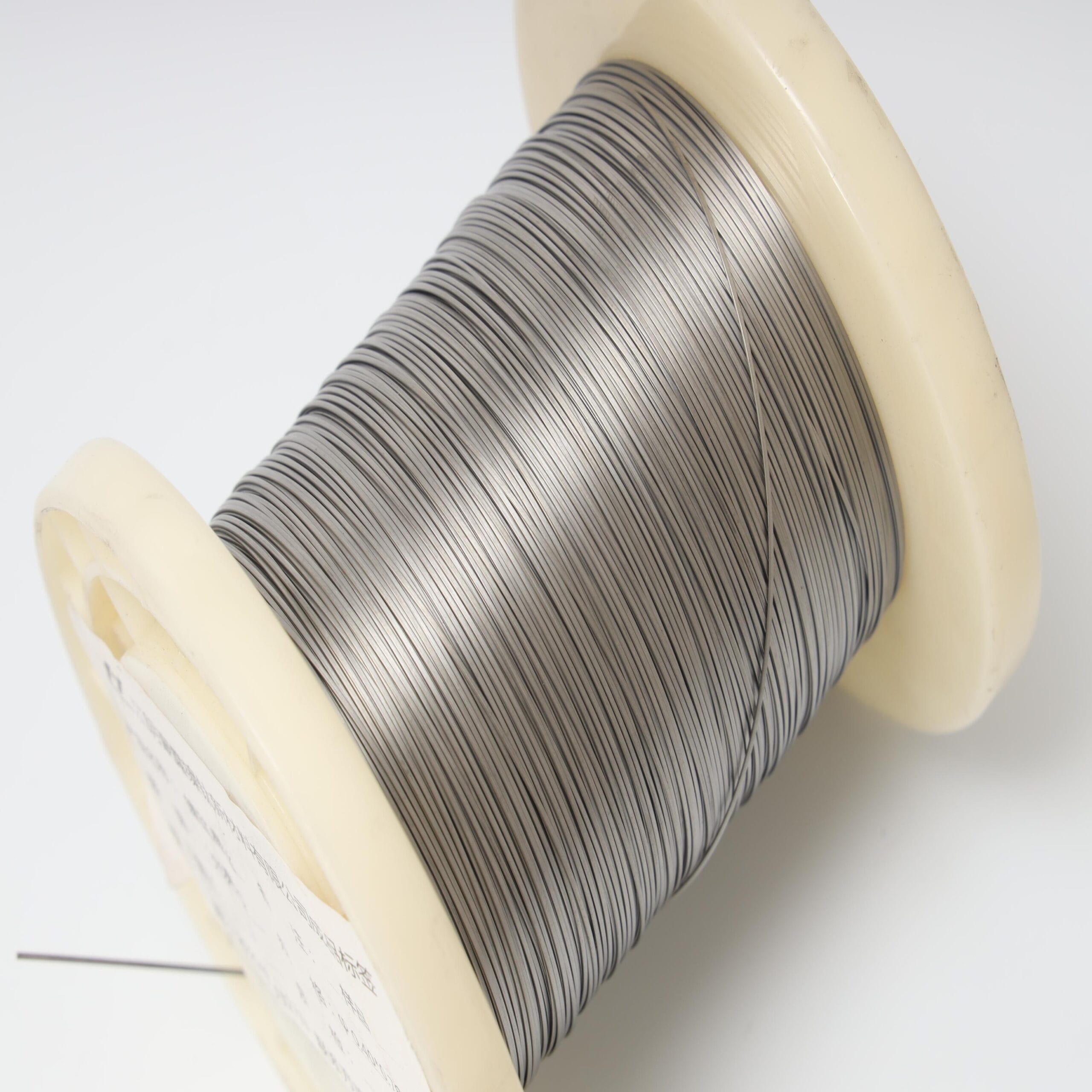

Nickel Titanium Trip Oxidized Nitinol Strips

Premium Nitinol Strips Suppliers for Demanding Applications

Materials

We manufacture our strips using high-quality Nickel Titanium alloy (Nitinol), known for its outstanding superelasticity, shape memory effect, and corrosion resistance. As trusted nitinol strips suppliers, we source materials from globally verified partners and rigorously test each batch to meet international industry standards.

Surface Finish – Trip Oxidized State

The advanced Trip Oxidized State surface treatment significantly enhances both durability and functionality. This advanced treatment forms a smooth, uniform oxide layer with three key benefits:

Reduces friction and wear

Improves biocompatibility

Increases resistance to harsh environmental conditions

This finish is ideal for long-term reliability, especially in critical medical and aerospace systems.

Strip Size Range

We offer Nitinol strips in a wide range of diameters, from 0.1 mm to 5.0 mm, with custom dimensions available to meet your exact specifications:

Thin Strips (0.1–1.0 mm): Ideal for medical devices and precision electronics

Thick Strips (1.0–5.0 mm): Suitable for aerospace components and industrial mechanisms

Applications

Our trip oxidized Nitinol strips serve high-performance sectors such as:

Medical Devices: Stents, guidewires, orthodontic archwires

Aerospace: Satellite components, vibration dampeners, actuators

Industrial Automation: Sensors, robotics, safety mechanisms

Consumer Electronics: Micro-springs, flexible connectors

As experienced nitinol strips suppliers, we understand application-specific requirements and provide tailored solutions.

Why Choose Us

Reliable Nitinol Strips Suppliers Since 2013

Certified Quality: ISO 13485-certified facility with 12+ strict quality checkpoints

Custom Solutions: Tailor strip composition, dimensions, and surface finishes to meet your exact requirements.

Rapid Delivery: 95% of orders ship within 72 hours

Technical Support: Engineers assist with alloy selection and design optimization

Competitive Pricing: Volume discounts and strategic partnership incentives

Technical Highlights

30% Higher Fatigue Life with Trip Oxidized Finish vs. standard Nitinol

Retains shape memory performance across 100,000+ actuation cycles

Reliable across -200°C to +250°C operating temperatures

Request Free Samples

Experience the quality difference first-hand. Contact us to request free nitinol strip samples today:

🌐 Visit: nitinolalloy.com

📧 Email: jyxiangfeng@gmail.com

📞 Response guaranteed within 4 business hours

▸ Facebook account:Facebook

Reviews

There are no reviews yet.