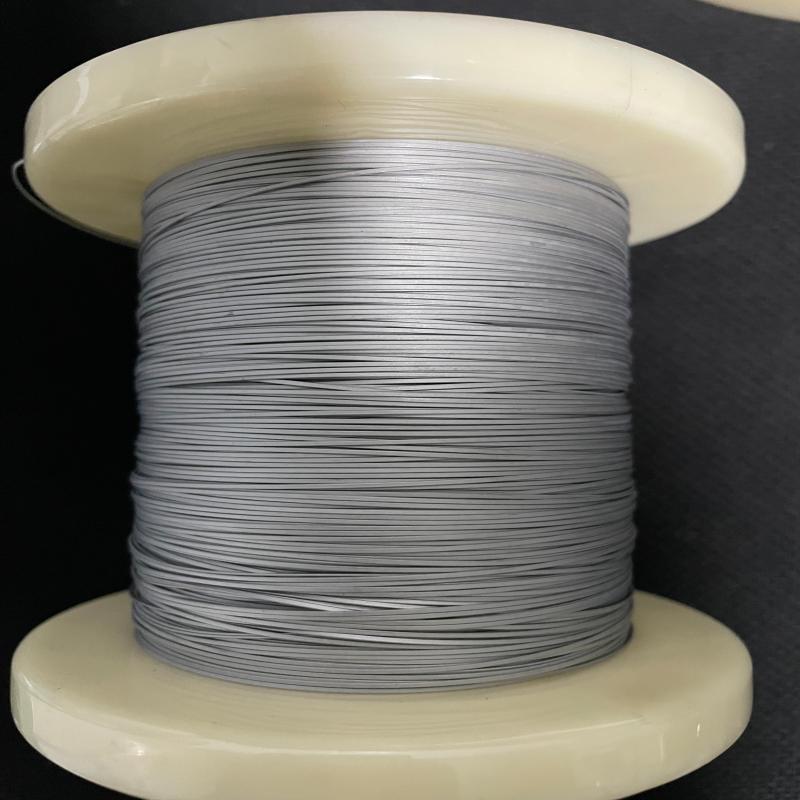

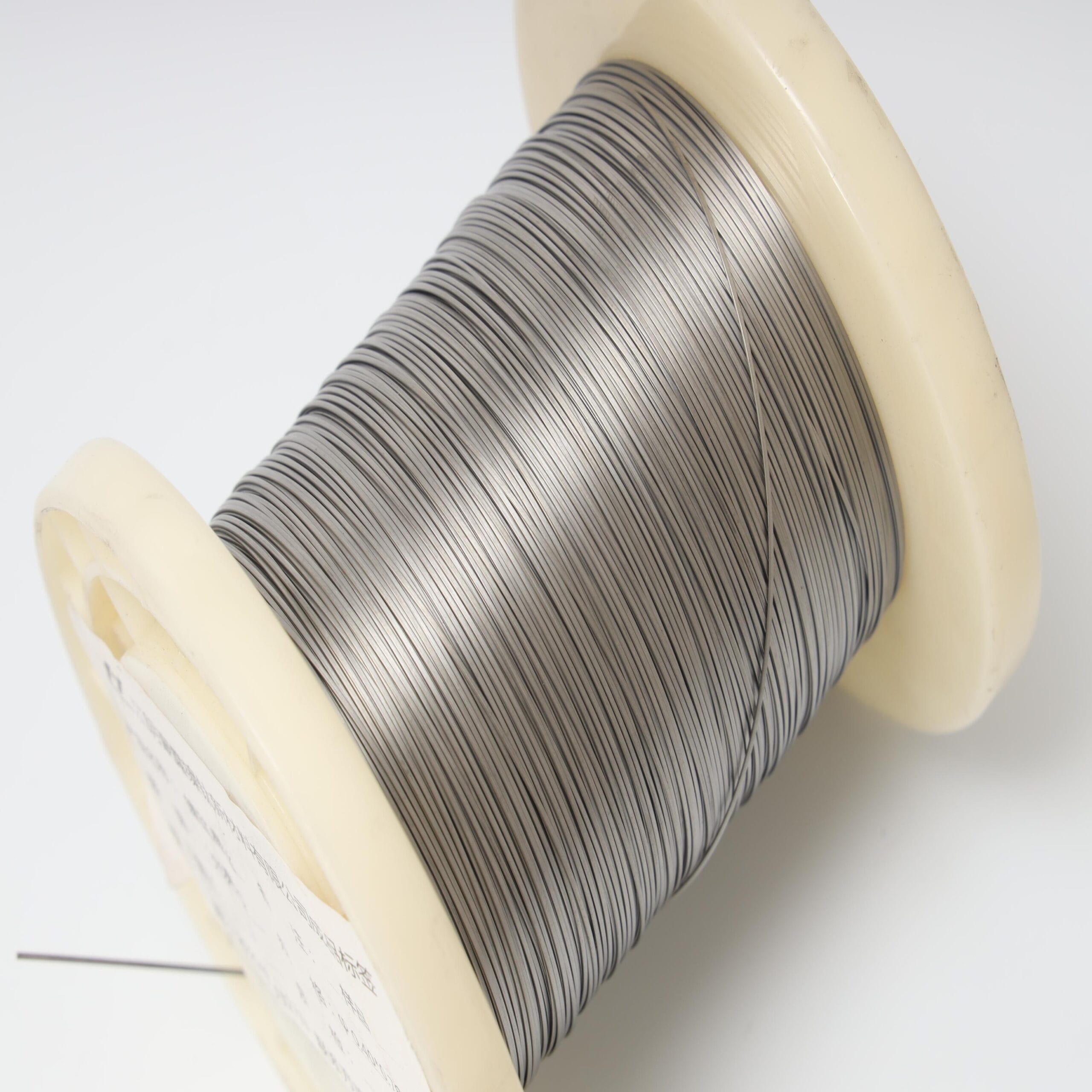

Flexible Strength for Innovation: Superelastic Nitinol Strips

Material Advantages

Our superelastic Nitinol strips are crafted from a precise nickel-titanium alloy, delivering unmatched flexibility, strength, and shape memory. These strips recover their original form even under extreme mechanical stress, offering excellent durability, thermal stability, and biocompatibility for demanding environments.

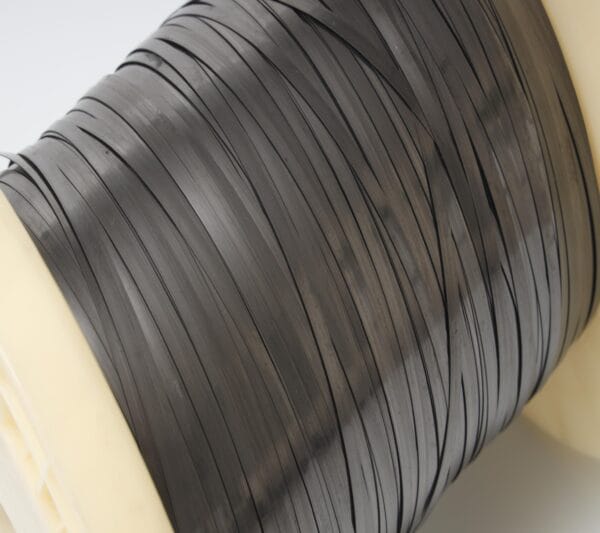

Surface Finish Options

Choose from a variety of surface finishes tailored to your application needs:

Acid-Etched Finish – Matte texture, perfect for enhanced bonding or coating.

Mechanical Polish – Smooth, low-friction surface for dynamic components.

Electropolished Finish – Mirror-like surface that resists corrosion and minimizes micro-defects.

Custom surface finishes are available upon request.

Available Dimensions

We offer Nitinol strips in thicknesses ranging from 0.1 mm to 5.0 mm:

Thin strips for precise medical instruments and microelectronics.

Thick strips for robust industrial and mechanical components.

All dimensions are manufactured with tight tolerances and can be customized to meet your exact specifications.

Versatile Applications of Nitinol Strips

Medical

Use in stents, catheter guidewires, orthodontic appliances, and surgical tools. The strips’ biocompatibility and fatigue resistance enhance patient safety.

Aerospace

Design high-performance actuators, valves, and sensors capable of withstanding extreme temperature and pressure variations.

Robotics

Implement into flexible joints, grippers, or springs for smooth, responsive movement in automated systems.

Consumer Electronics

Perfect for eyeglass frames, smartphone hinges, and wearables that require repeated flexing without failure.

Automotive

Enhance reliability and fuel efficiency in engine sensors, clutches, and vibration dampening components.

Why Choose Our Nitinol Strips?

✅ Consistent Quality

Each production batch undergoes strict quality control—verifying alloy composition, transformation temperatures, and mechanical properties in compliance with international standards.

✅ Tailored Customization

We accommodate custom dimensions, surface finishes, and processing methods—including cold working levels and heat treatments—for both prototyping and mass production.

✅ Rapid Delivery

Popular Nitinol strip sizes are stocked and ready to ship within 48 hours. No minimum order quantity required.

✅ Competitive Pricing

Efficient production methods and bulk raw material sourcing allow us to offer excellent prices—without compromising quality.

✅ Technical Expertise

Need help selecting materials or optimizing a design? Our team brings decades of experience in Nitinol welding, machining, and integration.

✅ Reliable, Long-Term Performance

Designed to endure millions of cycles, our strips maintain function in a wide temperature range from -50°C to 150°C.

✅ Sustainable Manufacturing

We prioritize sustainability through scrap recycling and energy-efficient production processes.

✅ Trusted by Global Leaders

Hospitals, aerospace manufacturers, and consumer tech companies worldwide depend on our Nitinol strips for their most critical applications.

Get Started Today

Enhance your next innovation with superelastic Nitinol strips.

📩 Request a quote, sample, or technical datasheet today—our team is ready to support your breakthrough.

Reviews

There are no reviews yet.